Range Rover Loyalty Assurance Programme, June 2008 – Replacing and Upgrading the Joint Connecting the Front Propeller Shaft to the Front Differential

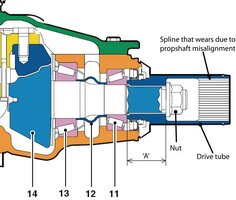

Although universally referred to as "the front diff. problem" this issue in fact relates to the spline connection between the front propshaft and the drive tube which drives the final drive pinion - the internals of the final drive/differential itself being problem-free.

Unlike its two predecessors, L322 has independent suspension and the front final drive/differential is bolted to the engine sump. The front propshaft transmits drive from the transfer case to the front differential and the two 'ends' form part of a rigid assembly with the engine & transmission - the propshaft is not therefore subject to suspension movement, etc. A semi-flexible joint is fitted at the transfer box end of the propshaft to cater for any misalignment.

In practice, it is possible for the front final drive/differential to be bolted to the sump at an angle which is too large for the semi-flexible joint to cope. The resulting misalignment between the drive tube and the propshaft results, over thousands of miles, in the spline fretting away until (and usually with very little warning) there is a sudden and total loss of drive.

Note - The transfer box is fitted with a Torsen differential to apportion the transmission's output torque (nominally 50:50) between the front & rear wheels. This type of differential is a torque bias type and splits the torque only within the range 35%F/65%R to 65%F/35%R. It cannot therefore 'lock' so when drive to the front wheels is lost it cannot provide any drive to the rear and the vehicle is left stranded.

Replacing the propshaft is straightforward enough but renewing the drive tube means disturbing the preload setting on the pinion bearings in the final drive so Land Rover decided to replace the complete final drive/differential at the same time (even though there was nothing wrong with it) rather than risk introducing another set of issues (i.e. pinion bearing failures and therefore potential bevel gear seizures) brought on by incorrect preload settings by the dealer technicians.

In June 2003, and again in February 2004, Land Rover released Service Bulletins to dealers on "Front Differential Alignment Procedure" as the required procedure for differential alignment during installation was not thoroughly covered in the RAVE Workshop Manual. This revised procedure should have guaranteed that any replacement propshafts would not be subject to subsequent failure. However, many people on bulletin boards report second - and even third - failures, with customers were being charged each time for the repair.

When Ford switched to the Jaguar engine and 6-speed transmission for 2006MY they took the opportunity to add a second flexible joint at the final drive/differential end of the front propshaft, thereby sorting the problem. Owners of '02-'05 Range Rovers, however, either continued to pay for replacement parts every XX thousand miles or try aftermarket solutions from companies such as Scott Colison in the USA or GKN Driveline in the UK who offered hardware solutions with a flexible joint at both ends of the shaft.

Immediately leading up to the 'Loyalty Assurance Programme' being introduced Land Rover were replacing failed propshafts (of the same design) free of charge, clearly finally admitting that a problem existed and then in June 2008 Land Rover began a programme of replacing, at no cost to the customer, the propshaft on all '02–'05 Range Rovers with a different design. The modification included a flexible joint at the differential end of the shaft, not dissimilar to the arrangement Land Rover had adopted from 2006MY onwards. A new flange design was required to drive the pinion in the final drive to accommodate the new joint which also involved the final drive being removed, modified and refitted as part of the 'enhancement/upgrade'.

Land Rover emphasised that this was not a 'recall' as such (presumably for legal reasons) but an 'upgrade' as part of their 'Loyalty Assurance Programme'. By December '08, however, in America it was reported as being a full recall : http://www.autoblog.com/2008/12/05/nearly-20-000-ranger-rovers-recalled/

Owners of '02 -'05 L322s should all have received a letter from Land Rover requesting their car be taken in for the replacement parts to be fitted. If for any reason you haven't received a letter, contact your local dealer. The vehicle is not required to be covered by any type of warranty, the work is done free of charge (in fact the Yanks are also given a $150 credit note for their trouble!) and you will be lent a courtesy car for the day. Land Rover has also set up a scheme to compensate owners who previously paid for a replacement propshaft/final drive (of the old design).

If you've recently purchased a 'previously enjoyed' (i.e. used) L322 and are unsure whether the modification has been carried out to your car then raise the suspension to the highest setting and use a mirror to take a look underneath. The photo below shows what you are looking for. Alternatively contact a dealer with your VIN and they should be able to tell you.

Although universally referred to as "the front diff. problem" this issue in fact relates to the spline connection between the front propshaft and the drive tube which drives the final drive pinion - the internals of the final drive/differential itself being problem-free.

Unlike its two predecessors, L322 has independent suspension and the front final drive/differential is bolted to the engine sump. The front propshaft transmits drive from the transfer case to the front differential and the two 'ends' form part of a rigid assembly with the engine & transmission - the propshaft is not therefore subject to suspension movement, etc. A semi-flexible joint is fitted at the transfer box end of the propshaft to cater for any misalignment.

In practice, it is possible for the front final drive/differential to be bolted to the sump at an angle which is too large for the semi-flexible joint to cope. The resulting misalignment between the drive tube and the propshaft results, over thousands of miles, in the spline fretting away until (and usually with very little warning) there is a sudden and total loss of drive.

Note - The transfer box is fitted with a Torsen differential to apportion the transmission's output torque (nominally 50:50) between the front & rear wheels. This type of differential is a torque bias type and splits the torque only within the range 35%F/65%R to 65%F/35%R. It cannot therefore 'lock' so when drive to the front wheels is lost it cannot provide any drive to the rear and the vehicle is left stranded.

Replacing the propshaft is straightforward enough but renewing the drive tube means disturbing the preload setting on the pinion bearings in the final drive so Land Rover decided to replace the complete final drive/differential at the same time (even though there was nothing wrong with it) rather than risk introducing another set of issues (i.e. pinion bearing failures and therefore potential bevel gear seizures) brought on by incorrect preload settings by the dealer technicians.

In June 2003, and again in February 2004, Land Rover released Service Bulletins to dealers on "Front Differential Alignment Procedure" as the required procedure for differential alignment during installation was not thoroughly covered in the RAVE Workshop Manual. This revised procedure should have guaranteed that any replacement propshafts would not be subject to subsequent failure. However, many people on bulletin boards report second - and even third - failures, with customers were being charged each time for the repair.

When Ford switched to the Jaguar engine and 6-speed transmission for 2006MY they took the opportunity to add a second flexible joint at the final drive/differential end of the front propshaft, thereby sorting the problem. Owners of '02-'05 Range Rovers, however, either continued to pay for replacement parts every XX thousand miles or try aftermarket solutions from companies such as Scott Colison in the USA or GKN Driveline in the UK who offered hardware solutions with a flexible joint at both ends of the shaft.

Immediately leading up to the 'Loyalty Assurance Programme' being introduced Land Rover were replacing failed propshafts (of the same design) free of charge, clearly finally admitting that a problem existed and then in June 2008 Land Rover began a programme of replacing, at no cost to the customer, the propshaft on all '02–'05 Range Rovers with a different design. The modification included a flexible joint at the differential end of the shaft, not dissimilar to the arrangement Land Rover had adopted from 2006MY onwards. A new flange design was required to drive the pinion in the final drive to accommodate the new joint which also involved the final drive being removed, modified and refitted as part of the 'enhancement/upgrade'.

Land Rover emphasised that this was not a 'recall' as such (presumably for legal reasons) but an 'upgrade' as part of their 'Loyalty Assurance Programme'. By December '08, however, in America it was reported as being a full recall : http://www.autoblog.com/2008/12/05/nearly-20-000-ranger-rovers-recalled/

Owners of '02 -'05 L322s should all have received a letter from Land Rover requesting their car be taken in for the replacement parts to be fitted. If for any reason you haven't received a letter, contact your local dealer. The vehicle is not required to be covered by any type of warranty, the work is done free of charge (in fact the Yanks are also given a $150 credit note for their trouble!) and you will be lent a courtesy car for the day. Land Rover has also set up a scheme to compensate owners who previously paid for a replacement propshaft/final drive (of the old design).

If you've recently purchased a 'previously enjoyed' (i.e. used) L322 and are unsure whether the modification has been carried out to your car then raise the suspension to the highest setting and use a mirror to take a look underneath. The photo below shows what you are looking for. Alternatively contact a dealer with your VIN and they should be able to tell you.

Attachments

Last edited by a moderator: