SeriesG

Offroader

I tightened up all the clutch parts, filled the master cylinder, and bled the system as per the manual. That didn't work at all so I reverted to the way my Dad taught me to do it and had it bubble-free in five minutes. Crack the bleeder and push down on the pedal, snug up the bleeder and let the pedal up slow. Repeat until fluid runs clear. No problem.

I immediately ran into another issue though: not enough rod adjustment available at the slave. I ended up having to make up a longer slave pushrod to get the pressure plate to cycle properly. Even though I went to the trouble of setting the release bearing actuator fork splines as per the factory specs it seems the outside arm on the gearbox isn't at an optimal angle. I think I'm out a spline or two and the gearbox arm is a little too "level". I think it should be pointing upward a bit.

It all seems to be working though and has that positive soft-then-stiff-then-soft again feel but the release bearing is hard against the pressure plate, which it shouldn't be. Not by much but it is contacting it. I'm not sure what is wrong but it sort of feels like the master cylinder doesn't have enough stroke to actuate the clutch properly. The pedal looks odd too being somewhat lower than the brake and no more adjustment available. Hmmm....

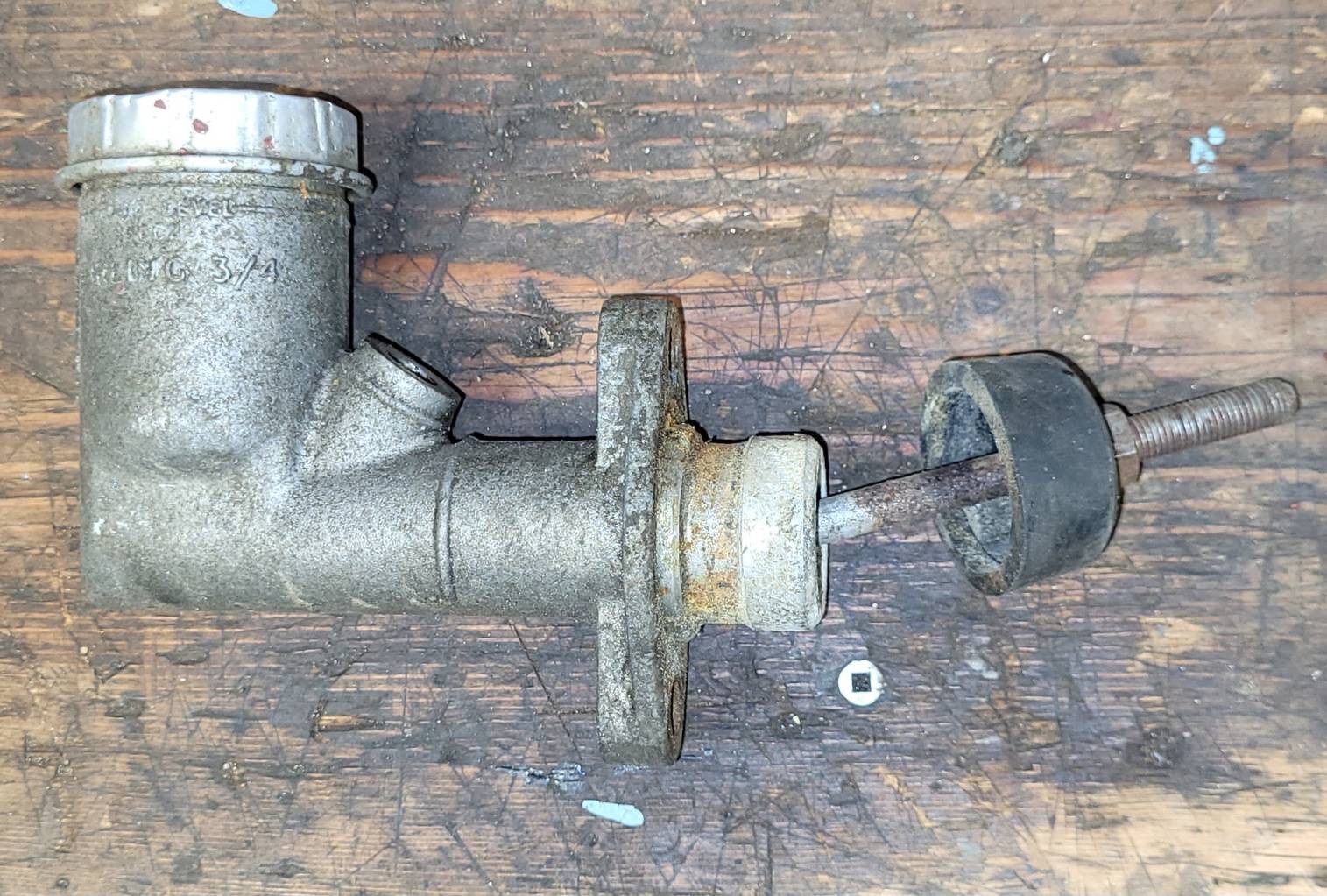

The clutch master cylinder that I chose was the same as what came out of it but I'm not entirely sure it's the correct one for this clutch system. I installed a 550732 which is listed as for a Defender as near as I can tell so that's odd. Perhaps it doesn't have enough travel or has too small of a bore for a Series IIa. This is the one that it came with:

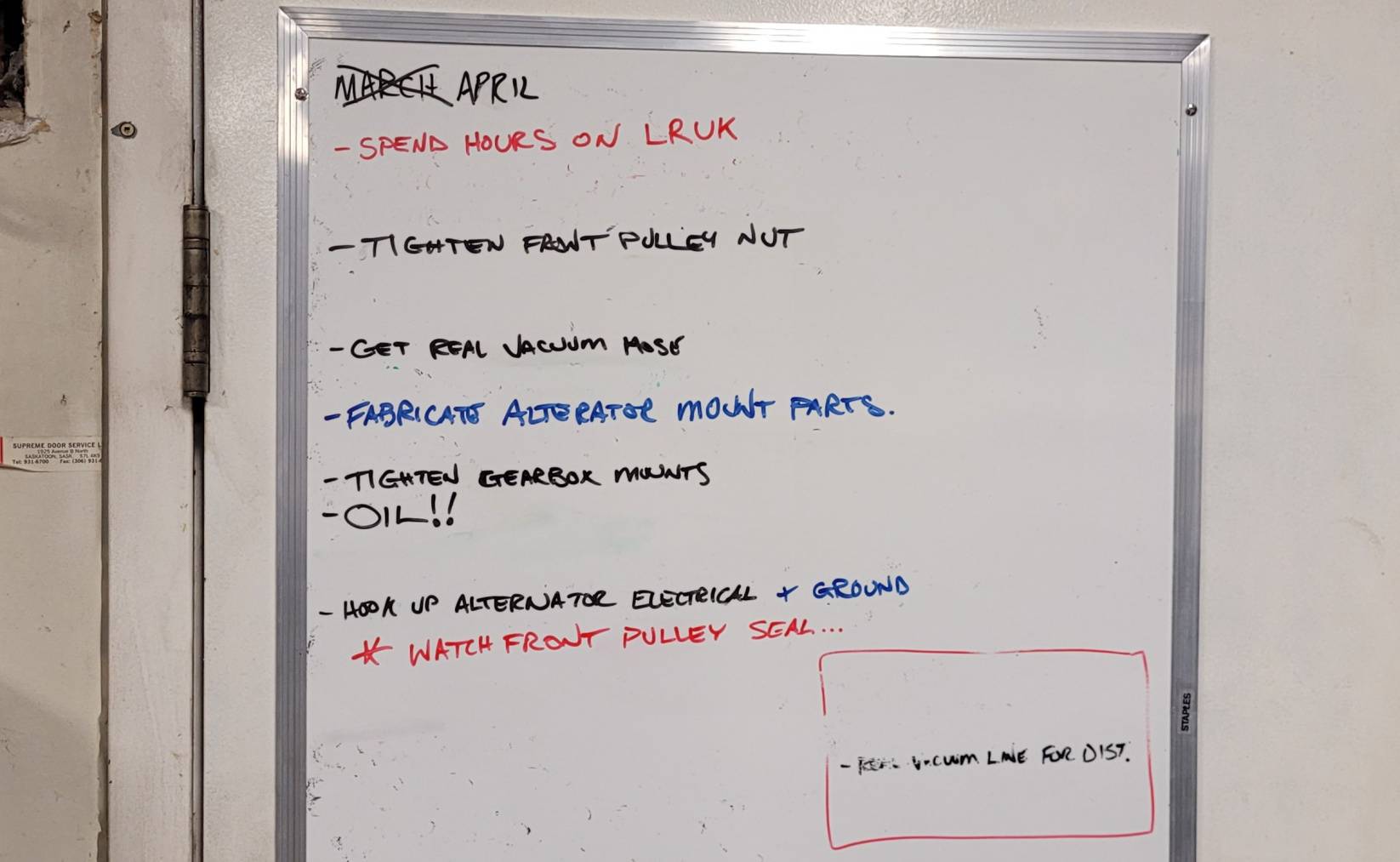

So I guess I'll keep on playing with the adjustments and see if I can get things working better. I want to make sure I've exhausted all my options before I tear out the gearbox and readjust the splined coupling on the release bearing fork, or go another direction with the clutch master. I think I'll walk away from it for the night and come back to it tomorrow with a clearer head. I've spent two days on this task that isn't even on my whiteboard and it looks like it'll need two more if I pull the gearbox. Unforeseen yet expected difficulties - the hallmark of working on fifty year old vehicles.

I immediately ran into another issue though: not enough rod adjustment available at the slave. I ended up having to make up a longer slave pushrod to get the pressure plate to cycle properly. Even though I went to the trouble of setting the release bearing actuator fork splines as per the factory specs it seems the outside arm on the gearbox isn't at an optimal angle. I think I'm out a spline or two and the gearbox arm is a little too "level". I think it should be pointing upward a bit.

It all seems to be working though and has that positive soft-then-stiff-then-soft again feel but the release bearing is hard against the pressure plate, which it shouldn't be. Not by much but it is contacting it. I'm not sure what is wrong but it sort of feels like the master cylinder doesn't have enough stroke to actuate the clutch properly. The pedal looks odd too being somewhat lower than the brake and no more adjustment available. Hmmm....

The clutch master cylinder that I chose was the same as what came out of it but I'm not entirely sure it's the correct one for this clutch system. I installed a 550732 which is listed as for a Defender as near as I can tell so that's odd. Perhaps it doesn't have enough travel or has too small of a bore for a Series IIa. This is the one that it came with:

So I guess I'll keep on playing with the adjustments and see if I can get things working better. I want to make sure I've exhausted all my options before I tear out the gearbox and readjust the splined coupling on the release bearing fork, or go another direction with the clutch master. I think I'll walk away from it for the night and come back to it tomorrow with a clearer head. I've spent two days on this task that isn't even on my whiteboard and it looks like it'll need two more if I pull the gearbox. Unforeseen yet expected difficulties - the hallmark of working on fifty year old vehicles.