SeriesG

Offroader

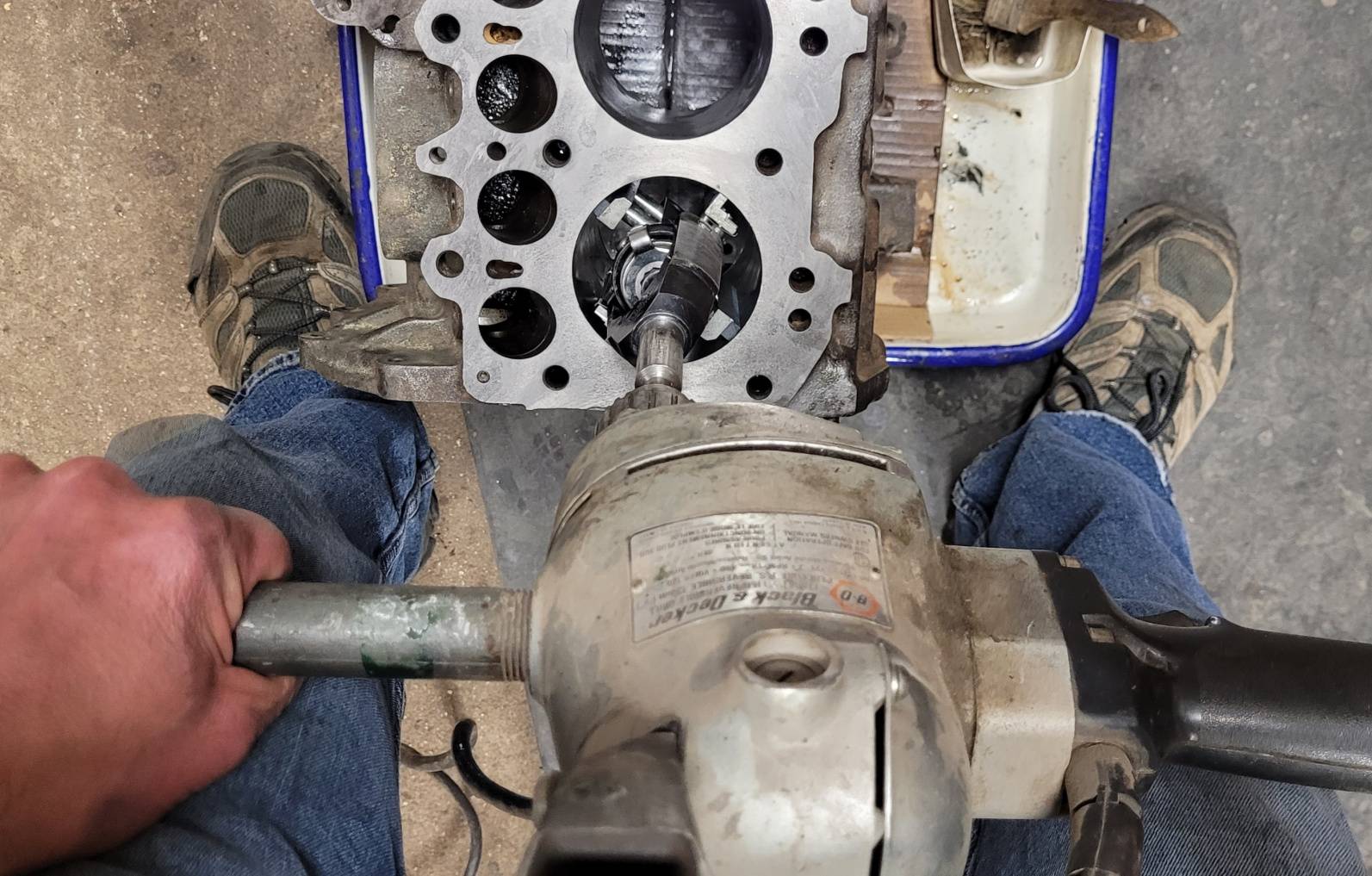

My mate dropped by and brought a Sunnen AN-604 portable hone mandrel - which is perfect - and a set of A45 stones, which is not exactly perfect but maybe close enough. Beggars can't be choosers.

Standard bore diameter is 3.562" so a 0.030" oversize should theoretically be 3.592". That seems to work out as the piston skirts measure 3.590" so with the 0.002" clearance called for in the manual adds up right. I bored the cylinders to 3.586" which leaves 0.006" to hone out. I probably should have left half that but this is my first try at this and I reckoned it's better to be safe than sorry.

Well... right now I'm feeling more sorry than safe. Ha! That six thou is quite a bit for this equipment. I'm glad now that I decided to bore most of it away because my original plan was to hone it all by hand and that would have been nasty. The A45 stones are 150 grit which from what I've read was good for roughing but these are cutting slowly and leaving a rather fine finish. Maybe it's because the stones are aluminum-oxide (for steel) where I should be using silicon-carbide (for cast iron). It's what I got...

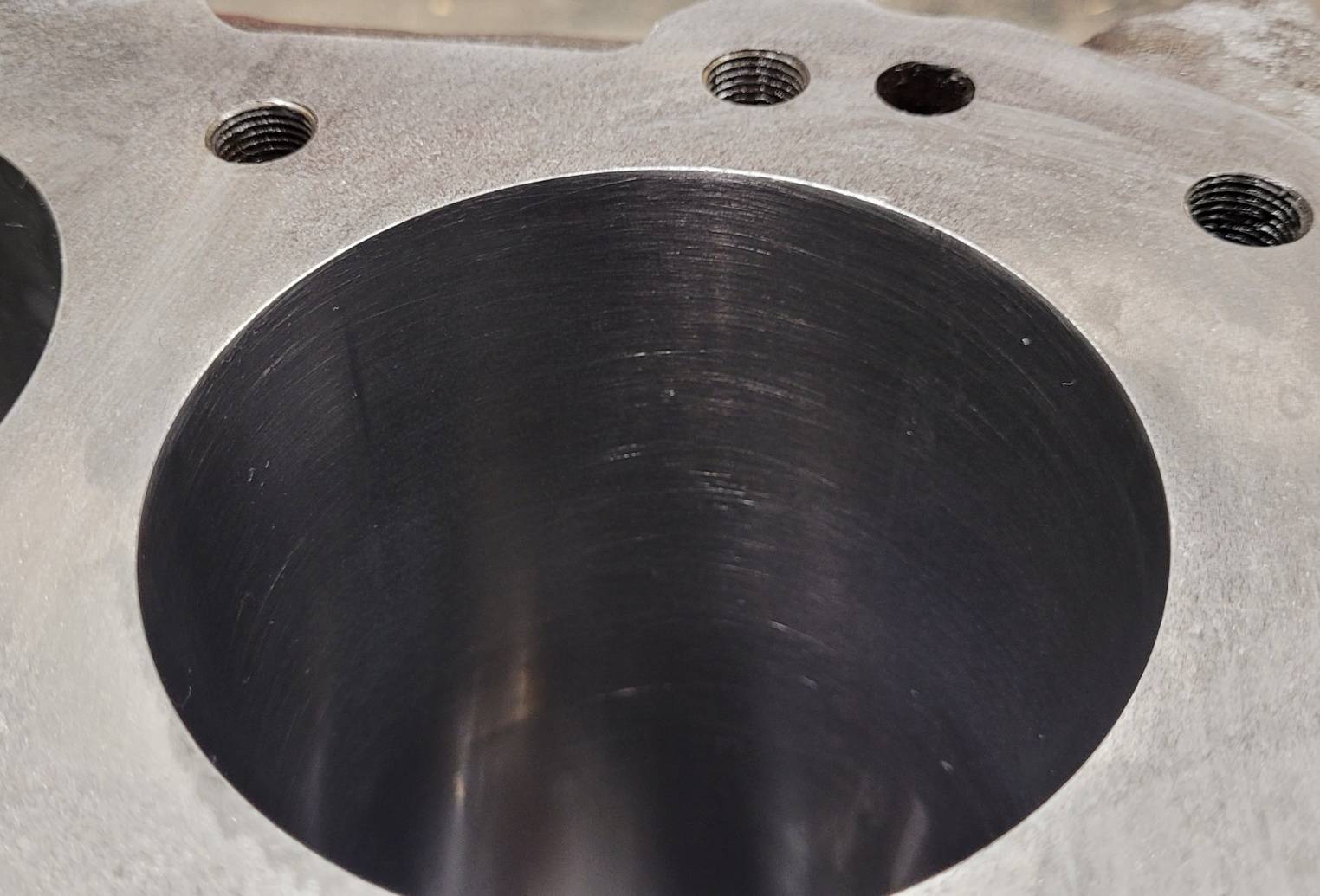

The first 0.004" came out relatively quickly but that last two thou was quite a fight. I think rather than wracking my body for the next ten hours I'll leave it till tomorrow and see if I can locate some coarser stones to speed things up a tad. At least bore #1 looks nice!

The thought of going to all this work and expense and using Britpart pistons is also weighing heavily on me. I really, really want to put this engine together but I've decided to order pistons from Turners instead. I'm also going to look into name-brand rings like Hastings or something like that. It's a bit of a bummer though because with all this online parts ordering the inevitable happened and my credit card was compromised so now I have to wait for a new one. That plus two weeks of delivery from Turners is going to delay my engine reassembly a good month. Oh well... there's plenty of other work to do while I wait.

So that's where I'm at right now. It's all quite good really. The machine work was successful, the honing is going reasonably well, and with the decision made on better quality pistons and rings I can sleep better knowing the bottom end of this engine shouldn't give me any trouble into the future.

Standard bore diameter is 3.562" so a 0.030" oversize should theoretically be 3.592". That seems to work out as the piston skirts measure 3.590" so with the 0.002" clearance called for in the manual adds up right. I bored the cylinders to 3.586" which leaves 0.006" to hone out. I probably should have left half that but this is my first try at this and I reckoned it's better to be safe than sorry.

Well... right now I'm feeling more sorry than safe. Ha! That six thou is quite a bit for this equipment. I'm glad now that I decided to bore most of it away because my original plan was to hone it all by hand and that would have been nasty. The A45 stones are 150 grit which from what I've read was good for roughing but these are cutting slowly and leaving a rather fine finish. Maybe it's because the stones are aluminum-oxide (for steel) where I should be using silicon-carbide (for cast iron). It's what I got...

The first 0.004" came out relatively quickly but that last two thou was quite a fight. I think rather than wracking my body for the next ten hours I'll leave it till tomorrow and see if I can locate some coarser stones to speed things up a tad. At least bore #1 looks nice!

The thought of going to all this work and expense and using Britpart pistons is also weighing heavily on me. I really, really want to put this engine together but I've decided to order pistons from Turners instead. I'm also going to look into name-brand rings like Hastings or something like that. It's a bit of a bummer though because with all this online parts ordering the inevitable happened and my credit card was compromised so now I have to wait for a new one. That plus two weeks of delivery from Turners is going to delay my engine reassembly a good month. Oh well... there's plenty of other work to do while I wait.

So that's where I'm at right now. It's all quite good really. The machine work was successful, the honing is going reasonably well, and with the decision made on better quality pistons and rings I can sleep better knowing the bottom end of this engine shouldn't give me any trouble into the future.