michaelridgeway

In Third Gear

Hi,

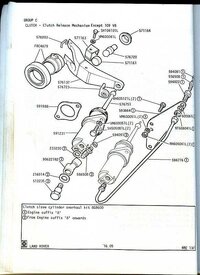

I have been experiencing increasingly alarming clutch judder on my 109 1982 2.25 petrol. Clutch was fine with plenty of travel left. Possibility of main engine oil seal shot, and ingin oil contaminating the clutch. Thats the worst case.

To eliminate other possibilities I have removed the slave cylinder and replaced it with a purchase from e bay (do I never learn?). No clutch. The shoulder is 14mm deep. Thats the bit which the two bolts connect through.

The original has a shouder 10mm deep and has the part number `0481 - Girling.` I can only guess this is preventing the connecting rod travelling far enough. Do I have to adjust the clutch at the master cylinder or do I need to get another slave cylinder? If so what part no. for Paddocks please? I have bled the system with an Eezi bleed kit but no travel.

Also does anybody know the bolt size for the slave. Curiouisly both are secure but turning. Do I need longer ones to compensate for the extra 4mm? Or have I just shredded the threads on the clutch housing?

Its a good job its not a b£$%^&d to get to.

Thanks

Mike R

I have been experiencing increasingly alarming clutch judder on my 109 1982 2.25 petrol. Clutch was fine with plenty of travel left. Possibility of main engine oil seal shot, and ingin oil contaminating the clutch. Thats the worst case.

To eliminate other possibilities I have removed the slave cylinder and replaced it with a purchase from e bay (do I never learn?). No clutch. The shoulder is 14mm deep. Thats the bit which the two bolts connect through.

The original has a shouder 10mm deep and has the part number `0481 - Girling.` I can only guess this is preventing the connecting rod travelling far enough. Do I have to adjust the clutch at the master cylinder or do I need to get another slave cylinder? If so what part no. for Paddocks please? I have bled the system with an Eezi bleed kit but no travel.

Also does anybody know the bolt size for the slave. Curiouisly both are secure but turning. Do I need longer ones to compensate for the extra 4mm? Or have I just shredded the threads on the clutch housing?

Its a good job its not a b£$%^&d to get to.

Thanks

Mike R