Got a small problem with the wiring to the rear wiper motor.

Would anybody be willing to take a picture of the 3 pin plug and its wiring for the back door wiper on a 110, please?

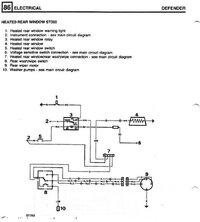

The wiring on my back door does not match the colours on the diagram and I am having difficulties trying to match things up.

cheers

Would anybody be willing to take a picture of the 3 pin plug and its wiring for the back door wiper on a 110, please?

The wiring on my back door does not match the colours on the diagram and I am having difficulties trying to match things up.

cheers