If your handbrake sticks on or is ineffective, chances are the expander unit is full of mud and general gunk that builds up over the years.

If your handbrake is ineffective then it might just be out of adjustment, so try turning the adjuster clockwise and seeing if it grips. If not then its time to strip it and clean it out!

Remove the rear prop, it's held on by 9/16ths nuts. You might have to undo 2/3 bolts and move the truck forward backward slightly to get access to the last bolt, it can be a bit awkward to get to if it's above the prop and the chassis/ rear tub can get in the way of the spanner. You only have to undo the prop at the handbrake end, there should be enough movement in the prop to be able to push it back into itself and tie it up out of the way. It might be stiff pushing it back into itself as it doesn't usually travel that far.

After you've removed the prop, you'll see that one or two big phillips head bolts (PH3) hold on the drum (number depends on the age of the vehicle).

They might be in tight, one way to loosen them is to hit the drum with a hammer whilst undoing them, the shock should free the bolts off.

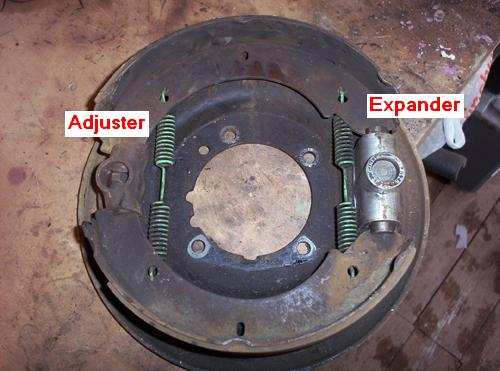

The pictures are taken with the handbrake assembly off the vehicle, its exactly the same as being on the vehicle, the only exception is the back plate will be bolted to the gearbox, and the drum will be bolted to the output flange on the transfer box. Apart from that, the handbrake is a separate unit from the gearbox.

After you have removed the drum, there will be two shoes with springs between them, holding them in place in the grooves of the expander and adjuster.

The easiest way to remove the shoes is to lift the top shoe out of the grove of either the expander first or the adjuster first, then lift the other side out. It's probably easier to remove the shoe out of the expander first because of the way it's designed. You might need to use a screwdriver or similar to lever the shoe out. Then, if you pull the bottom shoe down the two shoes should come off, still attached by the springs.

It's virtually impossible to remove the springs and then remove the shoes because of how the springs are designed to lock into the shoes, and also they're quite strong. The leverage of the shoe helps to spread the springs. Be aware that when you remove the shoes from the bottom of the expander or adjuster unit, the piston (and roller on the expander) might fall out! They probably wont at this stage, they're probably full of crud and that's why the handbrake is ineffective, but you never know!

With the shoes off, you're now free to remove the expander and the adjuster. You may as well clean the two since you've got this far! The expander is held on by three shims, the adjuster with two bolts. To get the expander off, you need to remove the shims with a screwdriver or a punch and a hammer, they're probably in tight. The bolts shouldn't be a problem on the adjuster.

*Remember which way the shims go in* I put mine back in wrong and one fell out!

Once the shims and bolts are removed, you can pull the expander and the adjuster off the backplate, you'll probably need to remove the rubber seal off the expander if it's still on! With these off the backplate, you now have to strip them down and clean them. Pull the pistons out of the expander, watch the rollers don't fall out and bounce under the workbench! With both of those out, pull the expander piston out (the one with the rod attached).

Soak them in a cleaner of some sort, I used a bit of petrol and soaked them whilst I stripped the adjuster. I had to soak them a few times as the grease and whatever was really stuck on!

The adjuster is the same design as the expander, only you don't have any rollers to fall out and lose! Pull the pistons out and put them to soak, you won't get them mixed up with the adjusters as they are different! Then unscrew the expander mechanism, screw it inwards, as if you were tightening it up (clockwise). The threaded rod will then drop out of the adjuster so you can soak that too.

Remember to soak the casings too, not just the pistons, they need to be clean inside as well. Get a screwdriver or something to scrape the crud off, then soak them and use a cloth round a screwdriver to clean it all out. Once this is all done, get some emery paper (sandpaper would do) and clean the pistons and rollers up so they're clean and also run it down inside the expander and adjuster casings. Remove any burrs off with a file, a burr would obviously cause the pistons to stick inside the casing.

Whilst these are soaking, have a look at the condition of the brake shoes. If there isn't any friction material on them, then that would be a factor of the ineffective handbrake. Similarly, if they appear shiny then they've been rubbing against the drum when it's been going round. Shiny friction material is smooth and will not grab the drum, so your handbrake won't work! You may be able to revive them by sanding the shiny bits down until it appears dull and feels abrasive. Again, if the rear output seal of the transferbox is worn and has contaminated the drum and the shoes are covered in grease or oil, they should be replaced. The oil will soak into the friction material so it's unlikely the shoes will be much good again. The shoes aren't a great deal of money anyway, so if they're in a bad way you may as well replace them now. If the rear output seal on the transferbox is still leaking that there's not much point of rebuilding the handbrake until this is fixed, else it will just contaminate the shoes again! You'll know before hand if its leaking though, oil will be dripping from the bottom of the drum when it's standing.

After this is done, you're now ready to put the expander and adjuster back together. You'll need an elastic band or a bit of wire or string to wrap round the pistons so they don't fall out. Grease the pistons, and inside the casing, with brake grease, or if you haven't got any, use copper grease. Brake grease is better though as copper grease has tiny bits of copper in and will eventually jam up the expander again, it will take a while though. Don't use normal grease though, it can get quite hot in the handbrake drum and the grease may melt and drip out or burn off. I've reassembled mine without any grease so you can see what's happening clearer. You could probably reassemble your without grease too, I don't know how long it would stay free though, but on the plus side without grease it wouldn't attract the as much dust.

Starting with the expander unit, you need to push the main expander piston with the rod on in first, make sure you get it in the right way, and the grooved bits are facing the holes where the pistons go into. If you hold it with the channels downwards, then the rod sticks out below the expander unit.

With this in, hold it in with your thumb and insert the one roller in down the channel.

Hold the expander tilted back slightly, so the roller stays in whilst you get the piston in! You need to put the piston in with the angle facing the top of the expander unit.

E.g., you need the biggest bit of the grove at the top, the smallest bit of the grove at the bottom, the groove on the piston and the expander piston should form a wedge type shape so the rollers expand the pistons. You can put them in 180 degrees out by mistake, the angle of the piston will just counteract the angle on the expander piston so they won't slide in and out! The grooves on the piston where the brake shoes go into should be horizontal, they will be as long as you've got the piston in correctly.

With this piston in place, hold it there so it doesn't fall out! You don't need to hold the expander piston; it should stay in there by pushing against the piston on the side. Repeat the process for the other side, roller in the groove and the piston in the same way as before. Hold both pistons in now and check if it's together correctly. To check, hold the pistons and pull the rod on the expander piston, the two side pistons should come out. They don't come out a huge amount, maybe 3-5mm each if that. If they don't move out at all or by a very small amount then you've got the side pistons in the wrong way round. If one side moves out and the other doesn't, you've got the side piston that doesn't move out in wrongly! With this done, wrap an elastic band or wire or whatever around the pistons, I ran it around the expander unit in the grooves where the shoes go so the wire wouldn't slip off.

Now the expander is rebuilt, put it to one side and rebuild the adjuster unit. This is the easy bit, screw the adjuster back into the housing, as far back as it will go. Drop the pistons in so the angles match the ones on the adjuster rod, and wrap wire or whatever round them to hold them in place.

Now you'll need to get them back on the backplate, as Haynes says, refitting is the opposite of removal! The adjuster is easy, just put it through the backplate and bolt it back in, you can only bolt it in one way as the holes are offset on the adjuster and the backplate. The expander is a bit of a fiddle though, you have to push the expander through the backplate and get the shims on, put them on the same way they came off. I think the easiest way is to put the big one on first, which has a grove in it, from the bottom upwards. Then lay the smaller one in it, and then put the last one in from the top down. I'm pretty sure this is how they come off, but I'm not 100% as I forgot the first time I did it and looked at another handbrake unit to see how they went. It might be reversed, with the big plate with a grove in it coming from the top down, not from the bottom up. Remember which way yours come off, take a photo if you think your gonna forget! It's a tight fit and annoying, as you need it tight to hold the expander in but as you knock the bottom one in, you tend to knock the top one out!

Once this is all back together, you'll need to put the shoes on. The same as getting it off, its easier to assemble the shoes and have them held together with the springs, you'll never get the springs on the shoes when its on there, and the bottom shoe will keep falling out whilst your trying to do it! Plus you'll have move leverage to get the shoes in, either with your hands or a screwdriver. The shoes and springs fit together like this…………..

The hooks on the springs come from behind the shoes and hold on the outside. Notice that the shoes need to go in a certain way, when you put them together there is more of a gap on the expander side, as the expander is wider than the adjuster. When you've got these together, put the bottom shoe in the adjuster and expander grooves. Then put the top shoe into the adjuster groove, or as near as the groove as you can, you might not be able to get it in properly until you lift the shoe in the expander groove on the other side.

Now push the shoe up and in the expander groove, the springs are quite stiff so you might need to use a screwdriver to jimmy it in. Watch you don't pinch your fingers, the shoes will slip in the grooves fairly sharply when they're near and it would smart a bit! Now get a screwdriver or grab the bottom shoe and pull it down, cut the wire or string and pull it out. Lift the top shoe up and pull the wire out from the grooves. Do the same with the adjuster.

Clean up the drum, where the shoes don't touch the drum it'll probably be rusty and have a lip on which stops the drum sliding over the shoes, so get this off with a wire brush on a drill or similar. Then, get the drum and slide it back over the shoes. Hopefully it'll slide on easily now you've removed the rust/ lip. Get it on square, it won't slide on if it's on an angle. If it's a bit tight, tap it on with a hammer, a few mm each side at a time so it doesn't go on at a big angle and get stuck! With this on, put the screws back in. It's easier to adjust the handbrake now when the rear prop is still off, as you can rotate it freely. Rotate the drum and screw the adjuster up until the shoes lock the drum, then back it off one or two clicks, the end of the expander is shaped like a pyramid as you've probably noticed, so back it off one or two sides. The drum shouldn't drag on the shoes, if it's just slightly catching its ok, but it shouldn't be stopping the drum spinning freely. With this adjusted, try the handbrake. It should lock the drum within a few clicks. If you want there to be more play in the handbrake, so it comes up further before it locks, the best way to do it is to adjust the cable to have a bit more free play. Put the prop back on and that should be that all being well! (Ideally, you should replace all the nuts with new. Don't be tempted to re-use old locknuts!)

Hopefully this guide has answered all your questions, and hopefully you now have a functioning handbrake! Sorry if I've taught some of you to suck eggs but peoples experience with mechanics vary greatly on the forum, so in my view, more detail and pictures are better than being vague!

If your handbrake is ineffective then it might just be out of adjustment, so try turning the adjuster clockwise and seeing if it grips. If not then its time to strip it and clean it out!

Remove the rear prop, it's held on by 9/16ths nuts. You might have to undo 2/3 bolts and move the truck forward backward slightly to get access to the last bolt, it can be a bit awkward to get to if it's above the prop and the chassis/ rear tub can get in the way of the spanner. You only have to undo the prop at the handbrake end, there should be enough movement in the prop to be able to push it back into itself and tie it up out of the way. It might be stiff pushing it back into itself as it doesn't usually travel that far.

After you've removed the prop, you'll see that one or two big phillips head bolts (PH3) hold on the drum (number depends on the age of the vehicle).

They might be in tight, one way to loosen them is to hit the drum with a hammer whilst undoing them, the shock should free the bolts off.

The pictures are taken with the handbrake assembly off the vehicle, its exactly the same as being on the vehicle, the only exception is the back plate will be bolted to the gearbox, and the drum will be bolted to the output flange on the transfer box. Apart from that, the handbrake is a separate unit from the gearbox.

After you have removed the drum, there will be two shoes with springs between them, holding them in place in the grooves of the expander and adjuster.

The easiest way to remove the shoes is to lift the top shoe out of the grove of either the expander first or the adjuster first, then lift the other side out. It's probably easier to remove the shoe out of the expander first because of the way it's designed. You might need to use a screwdriver or similar to lever the shoe out. Then, if you pull the bottom shoe down the two shoes should come off, still attached by the springs.

It's virtually impossible to remove the springs and then remove the shoes because of how the springs are designed to lock into the shoes, and also they're quite strong. The leverage of the shoe helps to spread the springs. Be aware that when you remove the shoes from the bottom of the expander or adjuster unit, the piston (and roller on the expander) might fall out! They probably wont at this stage, they're probably full of crud and that's why the handbrake is ineffective, but you never know!

With the shoes off, you're now free to remove the expander and the adjuster. You may as well clean the two since you've got this far! The expander is held on by three shims, the adjuster with two bolts. To get the expander off, you need to remove the shims with a screwdriver or a punch and a hammer, they're probably in tight. The bolts shouldn't be a problem on the adjuster.

*Remember which way the shims go in* I put mine back in wrong and one fell out!

Once the shims and bolts are removed, you can pull the expander and the adjuster off the backplate, you'll probably need to remove the rubber seal off the expander if it's still on! With these off the backplate, you now have to strip them down and clean them. Pull the pistons out of the expander, watch the rollers don't fall out and bounce under the workbench! With both of those out, pull the expander piston out (the one with the rod attached).

Soak them in a cleaner of some sort, I used a bit of petrol and soaked them whilst I stripped the adjuster. I had to soak them a few times as the grease and whatever was really stuck on!

The adjuster is the same design as the expander, only you don't have any rollers to fall out and lose! Pull the pistons out and put them to soak, you won't get them mixed up with the adjusters as they are different! Then unscrew the expander mechanism, screw it inwards, as if you were tightening it up (clockwise). The threaded rod will then drop out of the adjuster so you can soak that too.

Remember to soak the casings too, not just the pistons, they need to be clean inside as well. Get a screwdriver or something to scrape the crud off, then soak them and use a cloth round a screwdriver to clean it all out. Once this is all done, get some emery paper (sandpaper would do) and clean the pistons and rollers up so they're clean and also run it down inside the expander and adjuster casings. Remove any burrs off with a file, a burr would obviously cause the pistons to stick inside the casing.

Whilst these are soaking, have a look at the condition of the brake shoes. If there isn't any friction material on them, then that would be a factor of the ineffective handbrake. Similarly, if they appear shiny then they've been rubbing against the drum when it's been going round. Shiny friction material is smooth and will not grab the drum, so your handbrake won't work! You may be able to revive them by sanding the shiny bits down until it appears dull and feels abrasive. Again, if the rear output seal of the transferbox is worn and has contaminated the drum and the shoes are covered in grease or oil, they should be replaced. The oil will soak into the friction material so it's unlikely the shoes will be much good again. The shoes aren't a great deal of money anyway, so if they're in a bad way you may as well replace them now. If the rear output seal on the transferbox is still leaking that there's not much point of rebuilding the handbrake until this is fixed, else it will just contaminate the shoes again! You'll know before hand if its leaking though, oil will be dripping from the bottom of the drum when it's standing.

After this is done, you're now ready to put the expander and adjuster back together. You'll need an elastic band or a bit of wire or string to wrap round the pistons so they don't fall out. Grease the pistons, and inside the casing, with brake grease, or if you haven't got any, use copper grease. Brake grease is better though as copper grease has tiny bits of copper in and will eventually jam up the expander again, it will take a while though. Don't use normal grease though, it can get quite hot in the handbrake drum and the grease may melt and drip out or burn off. I've reassembled mine without any grease so you can see what's happening clearer. You could probably reassemble your without grease too, I don't know how long it would stay free though, but on the plus side without grease it wouldn't attract the as much dust.

Starting with the expander unit, you need to push the main expander piston with the rod on in first, make sure you get it in the right way, and the grooved bits are facing the holes where the pistons go into. If you hold it with the channels downwards, then the rod sticks out below the expander unit.

With this in, hold it in with your thumb and insert the one roller in down the channel.

Hold the expander tilted back slightly, so the roller stays in whilst you get the piston in! You need to put the piston in with the angle facing the top of the expander unit.

E.g., you need the biggest bit of the grove at the top, the smallest bit of the grove at the bottom, the groove on the piston and the expander piston should form a wedge type shape so the rollers expand the pistons. You can put them in 180 degrees out by mistake, the angle of the piston will just counteract the angle on the expander piston so they won't slide in and out! The grooves on the piston where the brake shoes go into should be horizontal, they will be as long as you've got the piston in correctly.

With this piston in place, hold it there so it doesn't fall out! You don't need to hold the expander piston; it should stay in there by pushing against the piston on the side. Repeat the process for the other side, roller in the groove and the piston in the same way as before. Hold both pistons in now and check if it's together correctly. To check, hold the pistons and pull the rod on the expander piston, the two side pistons should come out. They don't come out a huge amount, maybe 3-5mm each if that. If they don't move out at all or by a very small amount then you've got the side pistons in the wrong way round. If one side moves out and the other doesn't, you've got the side piston that doesn't move out in wrongly! With this done, wrap an elastic band or wire or whatever around the pistons, I ran it around the expander unit in the grooves where the shoes go so the wire wouldn't slip off.

Now the expander is rebuilt, put it to one side and rebuild the adjuster unit. This is the easy bit, screw the adjuster back into the housing, as far back as it will go. Drop the pistons in so the angles match the ones on the adjuster rod, and wrap wire or whatever round them to hold them in place.

Now you'll need to get them back on the backplate, as Haynes says, refitting is the opposite of removal! The adjuster is easy, just put it through the backplate and bolt it back in, you can only bolt it in one way as the holes are offset on the adjuster and the backplate. The expander is a bit of a fiddle though, you have to push the expander through the backplate and get the shims on, put them on the same way they came off. I think the easiest way is to put the big one on first, which has a grove in it, from the bottom upwards. Then lay the smaller one in it, and then put the last one in from the top down. I'm pretty sure this is how they come off, but I'm not 100% as I forgot the first time I did it and looked at another handbrake unit to see how they went. It might be reversed, with the big plate with a grove in it coming from the top down, not from the bottom up. Remember which way yours come off, take a photo if you think your gonna forget! It's a tight fit and annoying, as you need it tight to hold the expander in but as you knock the bottom one in, you tend to knock the top one out!

Once this is all back together, you'll need to put the shoes on. The same as getting it off, its easier to assemble the shoes and have them held together with the springs, you'll never get the springs on the shoes when its on there, and the bottom shoe will keep falling out whilst your trying to do it! Plus you'll have move leverage to get the shoes in, either with your hands or a screwdriver. The shoes and springs fit together like this…………..

The hooks on the springs come from behind the shoes and hold on the outside. Notice that the shoes need to go in a certain way, when you put them together there is more of a gap on the expander side, as the expander is wider than the adjuster. When you've got these together, put the bottom shoe in the adjuster and expander grooves. Then put the top shoe into the adjuster groove, or as near as the groove as you can, you might not be able to get it in properly until you lift the shoe in the expander groove on the other side.

Now push the shoe up and in the expander groove, the springs are quite stiff so you might need to use a screwdriver to jimmy it in. Watch you don't pinch your fingers, the shoes will slip in the grooves fairly sharply when they're near and it would smart a bit! Now get a screwdriver or grab the bottom shoe and pull it down, cut the wire or string and pull it out. Lift the top shoe up and pull the wire out from the grooves. Do the same with the adjuster.

Clean up the drum, where the shoes don't touch the drum it'll probably be rusty and have a lip on which stops the drum sliding over the shoes, so get this off with a wire brush on a drill or similar. Then, get the drum and slide it back over the shoes. Hopefully it'll slide on easily now you've removed the rust/ lip. Get it on square, it won't slide on if it's on an angle. If it's a bit tight, tap it on with a hammer, a few mm each side at a time so it doesn't go on at a big angle and get stuck! With this on, put the screws back in. It's easier to adjust the handbrake now when the rear prop is still off, as you can rotate it freely. Rotate the drum and screw the adjuster up until the shoes lock the drum, then back it off one or two clicks, the end of the expander is shaped like a pyramid as you've probably noticed, so back it off one or two sides. The drum shouldn't drag on the shoes, if it's just slightly catching its ok, but it shouldn't be stopping the drum spinning freely. With this adjusted, try the handbrake. It should lock the drum within a few clicks. If you want there to be more play in the handbrake, so it comes up further before it locks, the best way to do it is to adjust the cable to have a bit more free play. Put the prop back on and that should be that all being well! (Ideally, you should replace all the nuts with new. Don't be tempted to re-use old locknuts!)

Hopefully this guide has answered all your questions, and hopefully you now have a functioning handbrake! Sorry if I've taught some of you to suck eggs but peoples experience with mechanics vary greatly on the forum, so in my view, more detail and pictures are better than being vague!