You may notice oil coming out of your handbrake (transmission brake) drum. This will in all probability be a leak from the gearbox rear output shaft oil seal.

Later series models have an oil catcher on the output flange, and the oil is supposed to leak out of a hole in the casting, just in front of the handbrake backplate. If this gets blocked with mud or road dirt, then the leak will progress out through the drum and will also coat the brake shoes liberally with oil. If they are oiled up, then an MOT failure is on the cards as the handbrake will not grip as it should.

So, how to replace it? You'll need new shoes (best option), an oil seal, FRC 1780, (fits all standard Series models, even SI, but not V8 or one ton) a felt washer 622042, four propshaft bolt nuts NZ60641L (always replace these with new!) and possibly 6 new nuts for the drum, 50525.

First of all, Drain the oil from the transfer box, then chock the front wheels and lift one rear wheel off the ground….. Support the Landy with an axle stand because (yes, you guessed it) Squished folk don't get driving Landies!..... The reason for doing this is so that you can revolve the handbrake drum and propshaft. It makes it a whole lot easier to get at the bolts securing the propshaft. They will come undone using an open spanner, or a cranked ring spanner, but if you have one of the special sockets designed for the job, all well and good. The spanner method just takes a bit longer.

Once the nuts are off the propshaft slide it back in length (the splined end will probably ooze grease as you do this, if you have used grease regularly) then tie it up out of the way. Now undo the 6 nuts holding the drum to the output shaft, and remove it. It will come off easily if the handbrake isn't on!

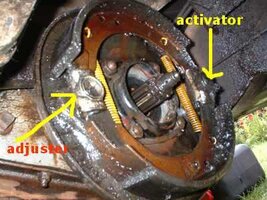

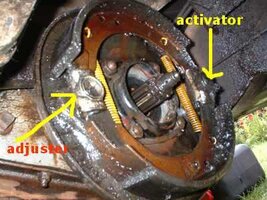

The above photo shows the result. There's a lot of oil in there, as the drain was blocked. That photo is of a late Series III's output shaft and brake setup.

Now, remove the split pin from the castle nut, and undo the nut. The output flange will come off easily… You'll notice there is a felt washer in there as well. Throw that away and remember to replace it with a new one.

This next photo shows the mess the oil leak can make, especially if you haven't cleaned the drain hole out!

And a quick look to see where the oil catcher is…

And now a look at the earlier type without the oil catcher…

You can see the difference quite easily.

Examine the output flange closely…if it is excessively scored you may need to replace it, as the lips of the seal run on it. If it's badly scored no amount of new seals will stop it leaking! Light wear is acceptable, but it's your decision!

The above is an early output flange. The flanges are the same throughout the series range (236630) from SI to SIII. The V8 box is different though, part number 576627. Later models have an oil catcher, which you can just see on the next photo. It's still the same flange though, the oil catcher is a press fit.

Okay, you now have the flange off, and can see the oil seal.

Remove the shoes, making careful note of how the springs are fitted, and which way round they are. I strongly suggest that you take great care removing the shoes on the adjuster side, as the adjuster on early models contains slides which will drop out if you are not careful, so tie them in place with a bit of wire. If they drop out it is possible to replace them the wrong way, and then it won't adjust evenly, so beware! (it's very difficult to know which way the right way is too…) The adjuster and activator are highlighted in the second photo in the article.

Remove the oil seal. It's a tight fit, you'll need a lever, and it will pop out when you least expect it, so be careful.

Stuff a lint free rag into the output shaft hole now, and spray the backplate with brake cleaner or degreaser to remove all the oil. You should clean out the drain hole for the oil catcher too at this point, and then dry everything off.

Replacing the seal is the same as any other oil seal. You must make sure it goes in evenly and squarely or it won't work. An ideal tool for this is the hub nut box spanner you use on the wheel hubs. It's just the right size to go over the output shaft and rest on the seal. Send the seal home until it is flush with the gearbox face. Oil the lips of the seal with EP90, as if it runs dry at first, it won't last long.

Now fit your new shoes, paying attention to the way the springs are fitted. It's easier to fit them with the output flange out of the way.

Refit the output flange, insert the felt washer, then the steel washer, and finally the castle nut. The output drive flange nut is torqued to 85lb/ft. Then fit a new split pin to the nut, and replace the drum. Don't refit the propshaft just yet.

You now need to adjust the shoes to accommodate the new linings. You might get away with it, as they don't wear the same as wheel brake shoes, but here's how you do it anyway.

On the passenger side (Right Hand Drive) of the gearbox there is a square headed adjuster nut on the backplate of the handbrake. Turn this clockwise until the shoes are in firm contact with the drum, and then back it off just enough to release the brake. That should be about two clicks.

Now apply the handbrake a few times, to centre the shoes. Ideally, it should operate after two clicks of the lever. If not this can be adjusted at the back of the handbrake lever, using the nut at the top of the vertical adjustment rod, I am afraid I don't have a photo of this at the moment, but it's fairly self explanatory. Tightening the nut down the adjuster rod will reduce the number of clicks required to activate the handbrake.

Now replace the propshaft, using the new nuts on the bolts.

That's the job done. I would suggest though that you check the handbrake after a few miles, just to make sure that the shoes are not binding on the drum. Keep adjusting until you get it right!

Later series models have an oil catcher on the output flange, and the oil is supposed to leak out of a hole in the casting, just in front of the handbrake backplate. If this gets blocked with mud or road dirt, then the leak will progress out through the drum and will also coat the brake shoes liberally with oil. If they are oiled up, then an MOT failure is on the cards as the handbrake will not grip as it should.

So, how to replace it? You'll need new shoes (best option), an oil seal, FRC 1780, (fits all standard Series models, even SI, but not V8 or one ton) a felt washer 622042, four propshaft bolt nuts NZ60641L (always replace these with new!) and possibly 6 new nuts for the drum, 50525.

First of all, Drain the oil from the transfer box, then chock the front wheels and lift one rear wheel off the ground….. Support the Landy with an axle stand because (yes, you guessed it) Squished folk don't get driving Landies!..... The reason for doing this is so that you can revolve the handbrake drum and propshaft. It makes it a whole lot easier to get at the bolts securing the propshaft. They will come undone using an open spanner, or a cranked ring spanner, but if you have one of the special sockets designed for the job, all well and good. The spanner method just takes a bit longer.

Once the nuts are off the propshaft slide it back in length (the splined end will probably ooze grease as you do this, if you have used grease regularly) then tie it up out of the way. Now undo the 6 nuts holding the drum to the output shaft, and remove it. It will come off easily if the handbrake isn't on!

The above photo shows the result. There's a lot of oil in there, as the drain was blocked. That photo is of a late Series III's output shaft and brake setup.

Now, remove the split pin from the castle nut, and undo the nut. The output flange will come off easily… You'll notice there is a felt washer in there as well. Throw that away and remember to replace it with a new one.

This next photo shows the mess the oil leak can make, especially if you haven't cleaned the drain hole out!

And a quick look to see where the oil catcher is…

And now a look at the earlier type without the oil catcher…

You can see the difference quite easily.

Examine the output flange closely…if it is excessively scored you may need to replace it, as the lips of the seal run on it. If it's badly scored no amount of new seals will stop it leaking! Light wear is acceptable, but it's your decision!

The above is an early output flange. The flanges are the same throughout the series range (236630) from SI to SIII. The V8 box is different though, part number 576627. Later models have an oil catcher, which you can just see on the next photo. It's still the same flange though, the oil catcher is a press fit.

Okay, you now have the flange off, and can see the oil seal.

Remove the shoes, making careful note of how the springs are fitted, and which way round they are. I strongly suggest that you take great care removing the shoes on the adjuster side, as the adjuster on early models contains slides which will drop out if you are not careful, so tie them in place with a bit of wire. If they drop out it is possible to replace them the wrong way, and then it won't adjust evenly, so beware! (it's very difficult to know which way the right way is too…) The adjuster and activator are highlighted in the second photo in the article.

Remove the oil seal. It's a tight fit, you'll need a lever, and it will pop out when you least expect it, so be careful.

Stuff a lint free rag into the output shaft hole now, and spray the backplate with brake cleaner or degreaser to remove all the oil. You should clean out the drain hole for the oil catcher too at this point, and then dry everything off.

Replacing the seal is the same as any other oil seal. You must make sure it goes in evenly and squarely or it won't work. An ideal tool for this is the hub nut box spanner you use on the wheel hubs. It's just the right size to go over the output shaft and rest on the seal. Send the seal home until it is flush with the gearbox face. Oil the lips of the seal with EP90, as if it runs dry at first, it won't last long.

Now fit your new shoes, paying attention to the way the springs are fitted. It's easier to fit them with the output flange out of the way.

Refit the output flange, insert the felt washer, then the steel washer, and finally the castle nut. The output drive flange nut is torqued to 85lb/ft. Then fit a new split pin to the nut, and replace the drum. Don't refit the propshaft just yet.

You now need to adjust the shoes to accommodate the new linings. You might get away with it, as they don't wear the same as wheel brake shoes, but here's how you do it anyway.

On the passenger side (Right Hand Drive) of the gearbox there is a square headed adjuster nut on the backplate of the handbrake. Turn this clockwise until the shoes are in firm contact with the drum, and then back it off just enough to release the brake. That should be about two clicks.

Now apply the handbrake a few times, to centre the shoes. Ideally, it should operate after two clicks of the lever. If not this can be adjusted at the back of the handbrake lever, using the nut at the top of the vertical adjustment rod, I am afraid I don't have a photo of this at the moment, but it's fairly self explanatory. Tightening the nut down the adjuster rod will reduce the number of clicks required to activate the handbrake.

Now replace the propshaft, using the new nuts on the bolts.

That's the job done. I would suggest though that you check the handbrake after a few miles, just to make sure that the shoes are not binding on the drum. Keep adjusting until you get it right!