I have recently decided to learn how to weld. For whatever reason it’s a skill I have never got round to trying. But now I am a Land Rover owner I reckon the time has come!

This is not intended to be a 'How to' thread. I know there are a lot of the Forum members are already masters of this skill, there are some lovely examples of the art on several current threads, but I thought it would be interesting to make a record of the learning experience from the view point of a complete novice……and may-be give some of the old hands the opportunity for a rye smile (or two) along the way. Who knows, there may be some of you thinking of doing your own welding, but haven’t made the leap. I hope this thread will help you to make an informed choice.

I will be delighted if everyone feels free to add their own experience(s), tips and recommendations, they will be most welcome and will help to fill out the knowledge required for the novice to get started with welding.

Where to start:

My starting point was to look at what I was likely to be working on. In my case this will be any of the steel work on my Landy that can, or has already been attacked by the rust worm. So the welding equipment needs enough punch to cope with steel up to 3mm thick but could be turned down for thinner material.

A MIG welder (metal inert gas welder) seemed the logical choice and there are a lot of options on the market. I settled on a 'Clarke' machine from Machine Mart

Not the cheapest, but it looked a very capable machine and had the option of different gauges of welding wire and gasses.

A few other things I found worth investing in are the excellent booklet by Chris Graham "Mig Welding, The Plain And Simple Guide". (thanks for the recommendation Big Sandy)

A decent welding mask, I went for one with an auto dim lens, which is adjustable for reaction time and sensitivity. It can also be used as a mask when grinding.

Mole grips, metal C-clamps and welding magnets (really good for holding awkward shaped items)

A pair of leather welders gloves, a leather apron and a sensible addition would be full arm length sleeve for the arm that holds the torch if you intend to do any welding upside down! as I found out……

That was through two layers of clothing. I also added was a spare tube of CO2 gas, extra spool of welding wire, spare shrouds and torch tips. And a can of spray that stops splatter sticking to the end of the torch. All in all just over £400.00 (with postage)

When the welder arrives there’s a bit of putting together, but it’s very straight ahead and well explained in the instructions that come with the machine. A couple of things to note:

When you feed the wire through the hose to the torch head, keep it as straight as you can, don’t force it through or it will kink.

Inside the machine there is a screw adjuster for the tension on the wire, don’t over tighten this.

The First Welds

A metal topped table/bench is ideal to work on. It gives a fire proof surface and a good earth connection. Keep a fire extinguisher handy too. The instructions include a chart to guide settings for different thicknesses of steel and other metals. I photocopied this and have stuck it inside the side door of the welder.

Ready to get going !!

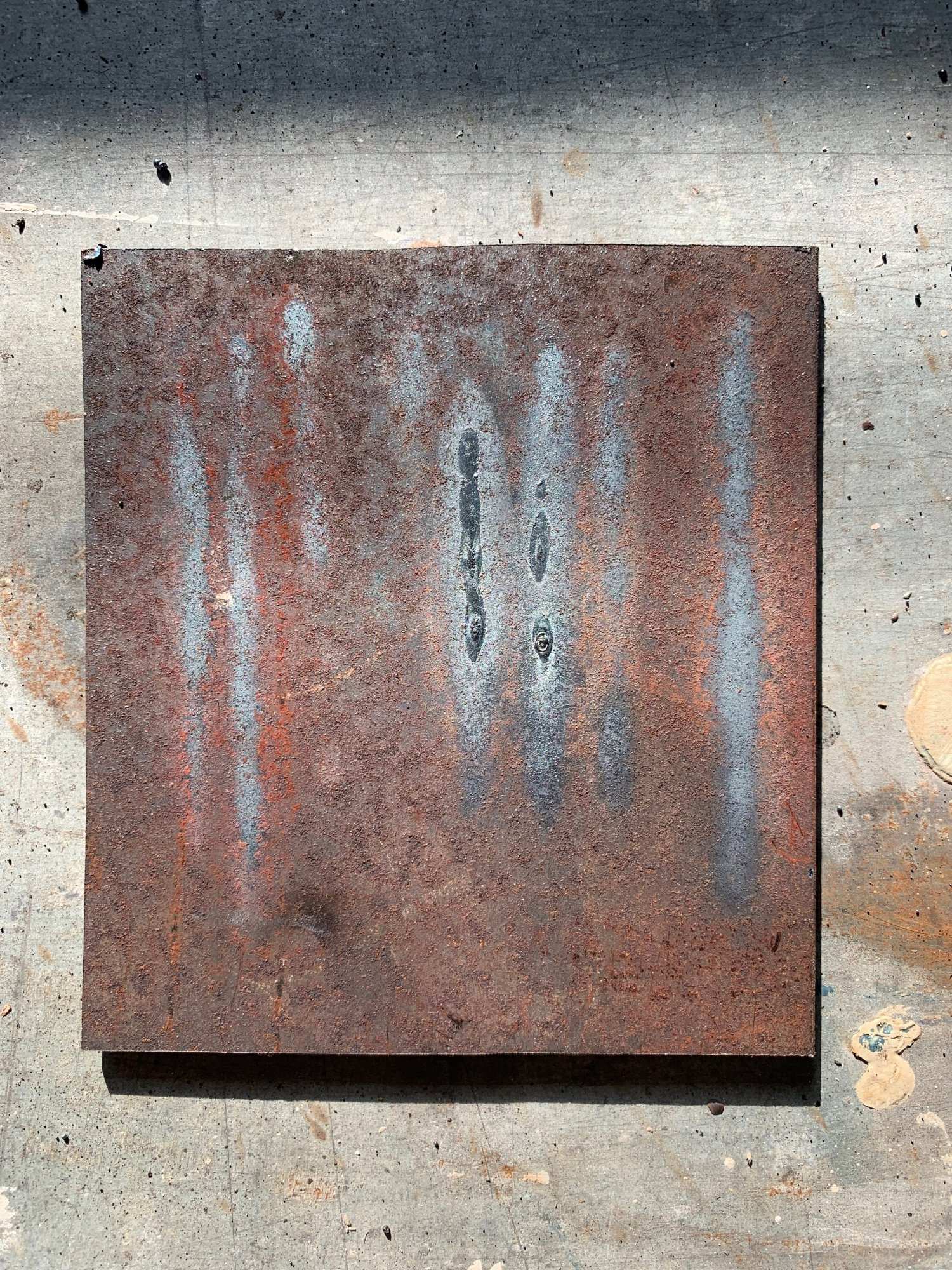

The best advice I have had so far is to practice as much as you can on bit of scrap steel. My first attempts are to run a weld across a steel plate. It’s 2mm thick.

Using a mask that fits on your head means both hands are free, this allows me to steady the torch hand. The instant darkness of the lens is a surprise, at first and trying to see what you are doing is tricky, initially. I found it very easy to just miss the joint line and end up with a run of weld on one side of the joint, this was a problem with butt joints, but being able to steady the torch head with my left hand helped.

I was also surprised by how close I had to get, sometimes, to the weld to be able to see how the joint was forming, but soon became confident that I wasn’t going to melt my face off.

The idea here was to see how different feed speeds of the wire would affect the resulting weld. The first run was the third in from the right, the last on was the one in the middle. You can see the flow is much more consistent in the middle seam. Each time I played with the wire feed speed until I got a steady ‘crackle’ as I ran the weld and got the movement of the torch head to the point where I had the ideal balance between wire speed, melt and penetration. When you turn the plate over, you can see that the last couple of welds have really penetrated the steel.

That was what I was after, a consistent run of weld with good penetration into the steel, but not to the point where a hole was burnt into it.

Next was to try joining different bits together…… a little hit and miss in places and not the tidiest work in the world, but good practice non the less.

It gradually gets better….

More practise required...........

This is not intended to be a 'How to' thread. I know there are a lot of the Forum members are already masters of this skill, there are some lovely examples of the art on several current threads, but I thought it would be interesting to make a record of the learning experience from the view point of a complete novice……and may-be give some of the old hands the opportunity for a rye smile (or two) along the way. Who knows, there may be some of you thinking of doing your own welding, but haven’t made the leap. I hope this thread will help you to make an informed choice.

I will be delighted if everyone feels free to add their own experience(s), tips and recommendations, they will be most welcome and will help to fill out the knowledge required for the novice to get started with welding.

Where to start:

My starting point was to look at what I was likely to be working on. In my case this will be any of the steel work on my Landy that can, or has already been attacked by the rust worm. So the welding equipment needs enough punch to cope with steel up to 3mm thick but could be turned down for thinner material.

A MIG welder (metal inert gas welder) seemed the logical choice and there are a lot of options on the market. I settled on a 'Clarke' machine from Machine Mart

Not the cheapest, but it looked a very capable machine and had the option of different gauges of welding wire and gasses.

A few other things I found worth investing in are the excellent booklet by Chris Graham "Mig Welding, The Plain And Simple Guide". (thanks for the recommendation Big Sandy)

A decent welding mask, I went for one with an auto dim lens, which is adjustable for reaction time and sensitivity. It can also be used as a mask when grinding.

Mole grips, metal C-clamps and welding magnets (really good for holding awkward shaped items)

A pair of leather welders gloves, a leather apron and a sensible addition would be full arm length sleeve for the arm that holds the torch if you intend to do any welding upside down! as I found out……

That was through two layers of clothing. I also added was a spare tube of CO2 gas, extra spool of welding wire, spare shrouds and torch tips. And a can of spray that stops splatter sticking to the end of the torch. All in all just over £400.00 (with postage)

When the welder arrives there’s a bit of putting together, but it’s very straight ahead and well explained in the instructions that come with the machine. A couple of things to note:

When you feed the wire through the hose to the torch head, keep it as straight as you can, don’t force it through or it will kink.

Inside the machine there is a screw adjuster for the tension on the wire, don’t over tighten this.

The First Welds

A metal topped table/bench is ideal to work on. It gives a fire proof surface and a good earth connection. Keep a fire extinguisher handy too. The instructions include a chart to guide settings for different thicknesses of steel and other metals. I photocopied this and have stuck it inside the side door of the welder.

Ready to get going !!

The best advice I have had so far is to practice as much as you can on bit of scrap steel. My first attempts are to run a weld across a steel plate. It’s 2mm thick.

Using a mask that fits on your head means both hands are free, this allows me to steady the torch hand. The instant darkness of the lens is a surprise, at first and trying to see what you are doing is tricky, initially. I found it very easy to just miss the joint line and end up with a run of weld on one side of the joint, this was a problem with butt joints, but being able to steady the torch head with my left hand helped.

I was also surprised by how close I had to get, sometimes, to the weld to be able to see how the joint was forming, but soon became confident that I wasn’t going to melt my face off.

The idea here was to see how different feed speeds of the wire would affect the resulting weld. The first run was the third in from the right, the last on was the one in the middle. You can see the flow is much more consistent in the middle seam. Each time I played with the wire feed speed until I got a steady ‘crackle’ as I ran the weld and got the movement of the torch head to the point where I had the ideal balance between wire speed, melt and penetration. When you turn the plate over, you can see that the last couple of welds have really penetrated the steel.

That was what I was after, a consistent run of weld with good penetration into the steel, but not to the point where a hole was burnt into it.

Next was to try joining different bits together…… a little hit and miss in places and not the tidiest work in the world, but good practice non the less.

It gradually gets better….

More practise required...........