Iam so glad I decided to scrap mine instead of getting into it like you have.

-

Welcome to the Land Rover UK Forums

You are currently viewing the site as a guest and some content may not be available to you.

Registration is quick and easy and will give you full access to the site and allow you to ask questions or make comments and join in on the conversation. If you would like to register then please Register Now

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cliff's Disco 2 thread

- Thread starter Cliff4WD

- Start date

I think you're doing a great job. Yep, it's frustrating, but just think what you'll have when it's finished! For me, the D2 is the perfect car. It does all I could ever want a car to do, plus the visibility is outstanding on lanes, it is easy to drive, comfortable and, well just a bloody good all-rounder. If I could buy a brand new D2, I'd never look at another car again... well, almost! I love mine and regret that it really is starting to show its age with rot in places where it shouldn't be. But the engine's as smooth as a smooth thing the steering's light, it's all but completely waterproof, now I've stripped out all the headlining and re-done the sunroofs. (They're pretty pathetic sunroofs, though, to be frank. They only open half way and the electric motors a re very vulnerable to filling with water. But, if I had the skill, I'd strip mine down and rebuild it on a galv chassis like I did with the Lightweight. But, I'm not, so I won't. Anyway, well done, keep at it, it's worth the pain.

Galv chassis and galv the main body. Would make an awesome machine for life.

German Grüner

Offroader

With leaks but no rust, haha!

Regards

Regards

We all know about the rubbish sunroofs, roof-bar seals, and various other water ingress areas, but in my case I believe that a lot of the rot that ate away at my scuttle, the bonnet fixing brackets, and windscreen surround, was due to a very badly fitted windscreen. I can only assume that a PO had a replacement screen fitted by one of the main firms supporting the insurance industry, and that the fitter had little idea how to correctly fit a screen to a Discovery 2. The instructions as laid out in RAVE are quite specific about the width and depth of the PVU bead that the screen is bedded onto, also that the top weather strip should be replaced and the 'A' pillar trim rubber seals. When I first did repairs to rust holes appearing in the scuttle and the bonnet hinges coming away, it was evident that rain water was getting to the wrong side of the screen. Clearly that water had also found its way to the places that are now rotten.

I'm also quite appalled by the standard of workmanship and the poor build quality of the vehicle; it's shocking just how poor some of the design elements are and how little attention has been given to protecting areas that are obviously vulnerable. I've been investigating a bit today while preparing for the offside repairs. I was hoping that I would get away with some minor patching but that was wishful thinking.

It didn't take too much digging to expose the rot this side is as bad. It has eaten through the single skin section of the footwell behind the accelerator pedal

Now this is a perfect example of what I mean by poor build quality and design. The body mounting bracket that supports the inner valance/arch is spot welded in place. There is an exposed seam between the bracket and the body parts around its entire edge, no seam sealant, and perfectly placed to catch all the road water and mud flung at it by the front wheels. A built-in 'rust trap' (planned obsolescence?). Obviously the vehicles are now 18-22 years old but it's striking how the zintec steel body panels are pristine where protected yet rotten in areas like this.

I note that the area I showed ...

... has the rust developing at that spot welded joint where the zinc coating would have been compromised, also note the paint spray pattern and that the rusty area was never painted!

The so-called drain holes in the scuttle have been bugging me as they are only any use if the vehicle is facing slightly downhill. I decided to get the wings off today and have a closer look.

It's not easy to see from the photo, but the oversized hole (circled) actually overlaps the base of the scuttle leaving a hole into the footwell, this has been blocked off with seam sealer; a big blob of it! Now what's that all about? Are these holes there as part of the manufacturing process, are they drains, or what?

The red arrow is the route that rain water takes if it gets behind the 'A' pillar trim (from the top corners or past the trim seals or running back from the bonnet side gutters).

Looking at the design of the air intake plenum and the open intake through the pollen filter, I don't see how it's possible to stop water flooding through into the scuttle. If the screen is perfectly sealed, water will still make its way through as well as running off the rubber side chutes and into the bonnet side gutters. On this basis, I decided to add an extra pair of drain holes so that the water can escape if parked facing uphill.

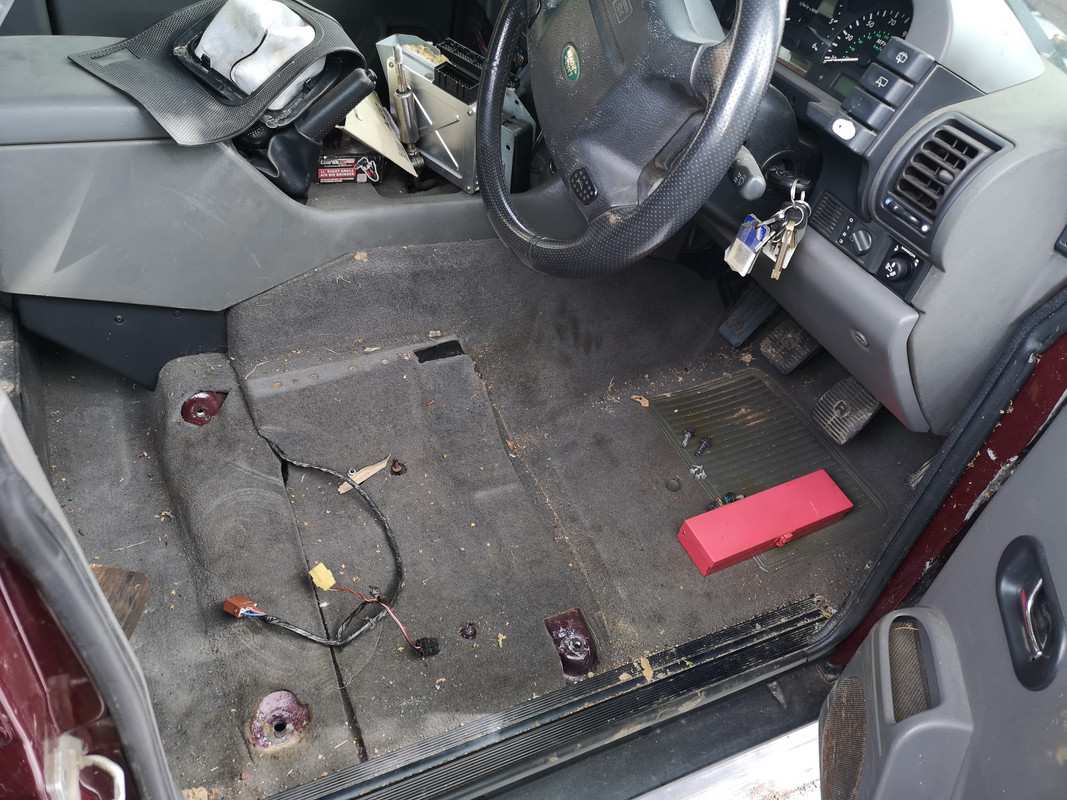

I had to get the seat and carpet out ready for welding ...

... and to get a better look at the extent of the rot from inside

I'm now thinking I should probably go the whole hog and get the entire dash out, just not sure the effort is worth it now I'v already struggled to do the repairs with it in. That's for another day now anyway, as it's started to rain again so time to tidy up. TTFN.

I'm also quite appalled by the standard of workmanship and the poor build quality of the vehicle; it's shocking just how poor some of the design elements are and how little attention has been given to protecting areas that are obviously vulnerable. I've been investigating a bit today while preparing for the offside repairs. I was hoping that I would get away with some minor patching but that was wishful thinking.

It didn't take too much digging to expose the rot this side is as bad. It has eaten through the single skin section of the footwell behind the accelerator pedal

Now this is a perfect example of what I mean by poor build quality and design. The body mounting bracket that supports the inner valance/arch is spot welded in place. There is an exposed seam between the bracket and the body parts around its entire edge, no seam sealant, and perfectly placed to catch all the road water and mud flung at it by the front wheels. A built-in 'rust trap' (planned obsolescence?). Obviously the vehicles are now 18-22 years old but it's striking how the zintec steel body panels are pristine where protected yet rotten in areas like this.

I note that the area I showed ...

... has the rust developing at that spot welded joint where the zinc coating would have been compromised, also note the paint spray pattern and that the rusty area was never painted!

The so-called drain holes in the scuttle have been bugging me as they are only any use if the vehicle is facing slightly downhill. I decided to get the wings off today and have a closer look.

It's not easy to see from the photo, but the oversized hole (circled) actually overlaps the base of the scuttle leaving a hole into the footwell, this has been blocked off with seam sealer; a big blob of it! Now what's that all about? Are these holes there as part of the manufacturing process, are they drains, or what?

The red arrow is the route that rain water takes if it gets behind the 'A' pillar trim (from the top corners or past the trim seals or running back from the bonnet side gutters).

Looking at the design of the air intake plenum and the open intake through the pollen filter, I don't see how it's possible to stop water flooding through into the scuttle. If the screen is perfectly sealed, water will still make its way through as well as running off the rubber side chutes and into the bonnet side gutters. On this basis, I decided to add an extra pair of drain holes so that the water can escape if parked facing uphill.

I had to get the seat and carpet out ready for welding ...

... and to get a better look at the extent of the rot from inside

I'm now thinking I should probably go the whole hog and get the entire dash out, just not sure the effort is worth it now I'v already struggled to do the repairs with it in. That's for another day now anyway, as it's started to rain again so time to tidy up. TTFN.

I almost forgot my update on the nearside ball joint replacement.

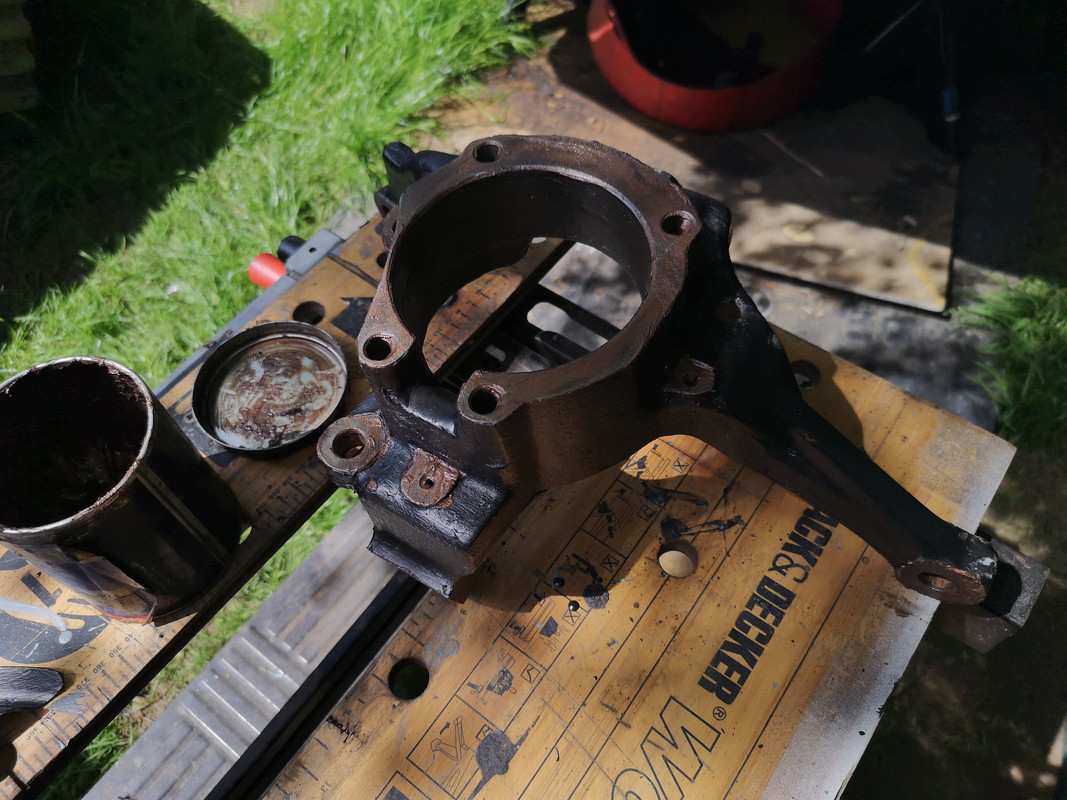

I carried on with the cleaning and refurbishing and got some chassis black on the zinc primed parts

The steering knuckle looks a bit more respectable now

A bit of paint on the axle parts

and then refitted knuckle

Backplate on next

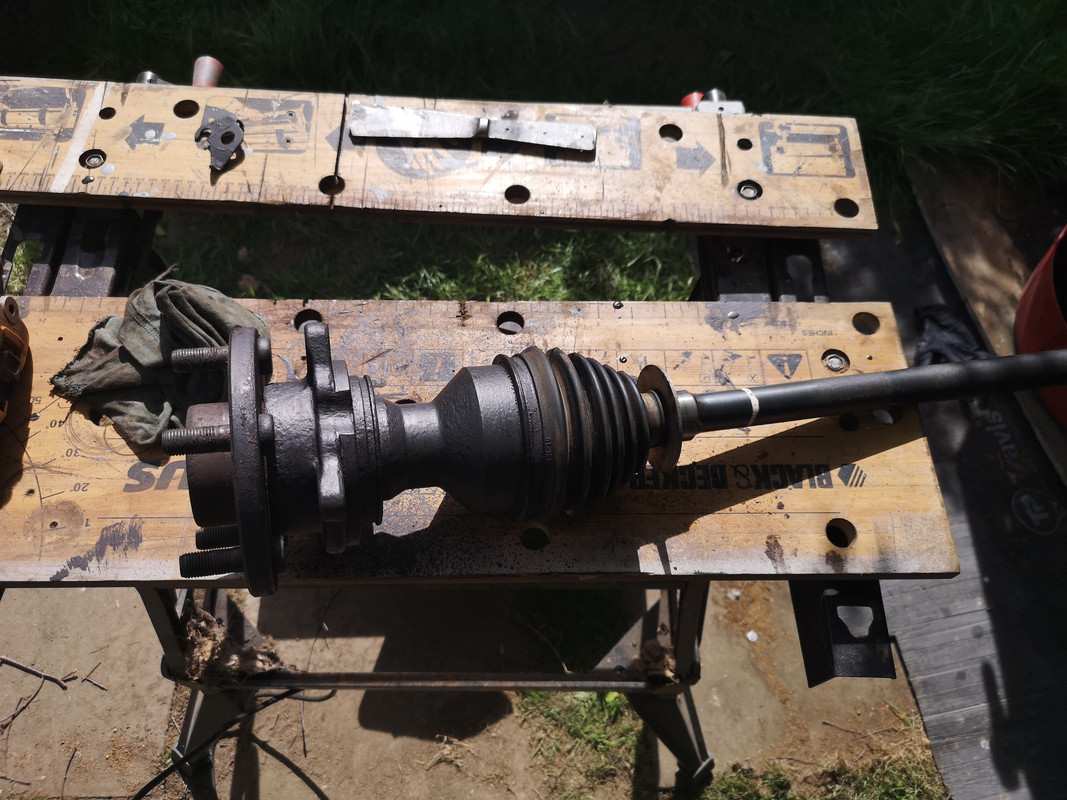

I then tidied up the drive shaft CV and hub assembly

Now, not wishing to teach anyone to suck eggs, but I did make a silly schoolboy error when re-fitting the hub. I had put the knuckle on and torqued up to spec but hadn't pressed it up tight on the tapers How embarrassing! What I was thinking of I don't know, so for the benefit of anyone as daft as me, make sure you use a suitable clamping tool or something to pull the knuckle up tight. The gap between the yokes should be something like this when fully home ...

... and the knuckle should be centred in line with the axle casing seal and the diff gear.

I stupidly struggled trying to get the CV housing past the bottom ball joint because I hadn't done those things.

Eventually it was in ...

... and then the brake disc

I then realised that the brake caliper and carrier were not moving freely, so time to service that.

Carrier off and wire brushed

caliper same

and some paint

It was then all reassembled with cleaned and lubed slide pins and anti seize where it matters (not on the slide pins, I used proper grease for them).

That was the job I originally set out to do; replace ball joints due to MOT advisory regarding the perishing dust covers. Glad that's done at least.

I carried on with the cleaning and refurbishing and got some chassis black on the zinc primed parts

The steering knuckle looks a bit more respectable now

A bit of paint on the axle parts

and then refitted knuckle

Backplate on next

I then tidied up the drive shaft CV and hub assembly

Now, not wishing to teach anyone to suck eggs, but I did make a silly schoolboy error when re-fitting the hub. I had put the knuckle on and torqued up to spec but hadn't pressed it up tight on the tapers How embarrassing! What I was thinking of I don't know, so for the benefit of anyone as daft as me, make sure you use a suitable clamping tool or something to pull the knuckle up tight. The gap between the yokes should be something like this when fully home ...

... and the knuckle should be centred in line with the axle casing seal and the diff gear.

I stupidly struggled trying to get the CV housing past the bottom ball joint because I hadn't done those things.

Eventually it was in ...

... and then the brake disc

I then realised that the brake caliper and carrier were not moving freely, so time to service that.

Carrier off and wire brushed

caliper same

and some paint

It was then all reassembled with cleaned and lubed slide pins and anti seize where it matters (not on the slide pins, I used proper grease for them).

That was the job I originally set out to do; replace ball joints due to MOT advisory regarding the perishing dust covers. Glad that's done at least.

Dash out day today. I should have just dug deep right from the start and got this out of the way but it's such a faff. A deep intake of breath and I got stuck in.

Took out the instrument pod and got the steering wheel off

After removing several nuts and bolts and unplugging connectors, I had to call SWMBO to give me a hand lifting the dash out of the vehicle

She moaned quite a bit bless her, but it's a 2 person job to manoeuvre it out over the gear sticks, handbrake lever, and out through the door (she had the tree in the way too :lol1: )

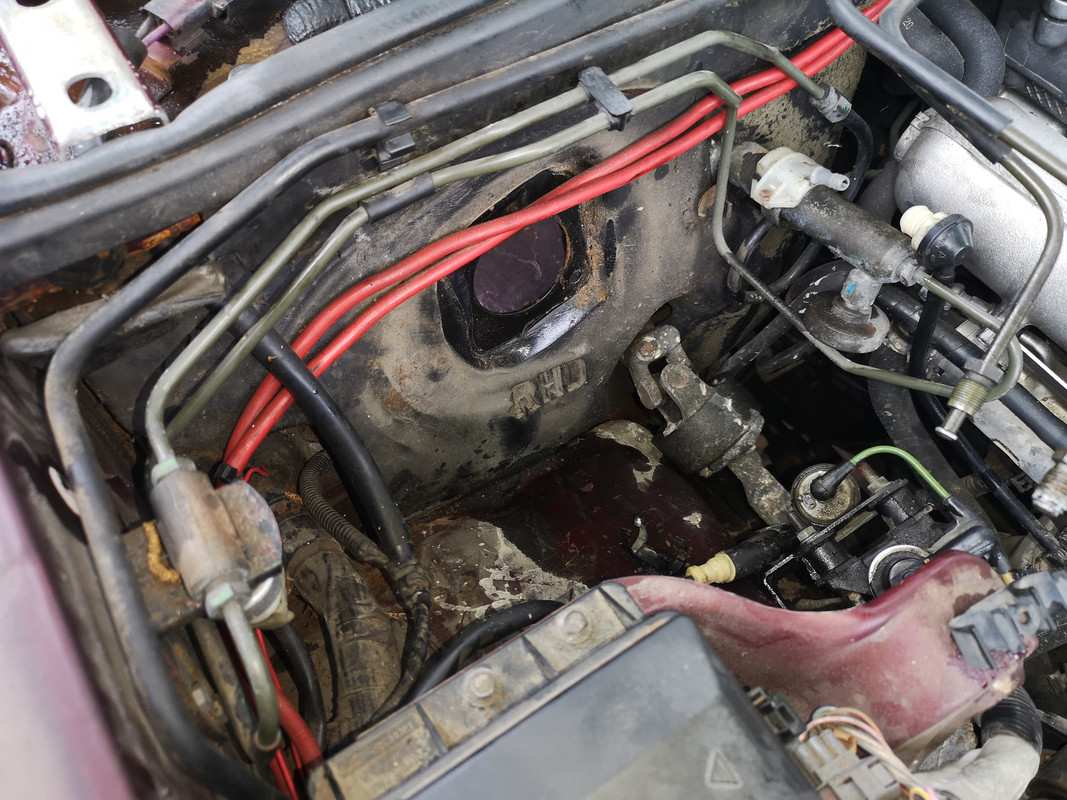

This is what it looks like behind it now it's out the way

I always worried what I was not dealing with when I repaired the windscreen surround and detached bonnet hinges (you'll have to look back in my thread to see what I'm talking about). Obviously with the dash in place, there was no access to deal with whatever was going on inside. I'm paying the price now.

Right hand ...

... and left hand

Pretty ugly

The way the bulkhead is constructed there is a hollow area. Water was able to get inside via the rotten corner and start the rot along the spot welded seam. Even though I thought I'd cut out the rot and welded in new steel, I had obviously missed some and it continued to rot from inside.

It might have made life easier to have just taken the dash out before I started my footwell repairs as It's a sight easier to see and access with it out of the way.

That's enough for today. Next I have to decide what to cut out and replace. I'm also starting to worry how I'll get the whole thing put back together. Maybe I should start a spare parts business! :think: :lolno:

Took out the instrument pod and got the steering wheel off

After removing several nuts and bolts and unplugging connectors, I had to call SWMBO to give me a hand lifting the dash out of the vehicle

She moaned quite a bit bless her, but it's a 2 person job to manoeuvre it out over the gear sticks, handbrake lever, and out through the door (she had the tree in the way too :lol1: )

This is what it looks like behind it now it's out the way

I always worried what I was not dealing with when I repaired the windscreen surround and detached bonnet hinges (you'll have to look back in my thread to see what I'm talking about). Obviously with the dash in place, there was no access to deal with whatever was going on inside. I'm paying the price now.

Right hand ...

... and left hand

Pretty ugly

The way the bulkhead is constructed there is a hollow area. Water was able to get inside via the rotten corner and start the rot along the spot welded seam. Even though I thought I'd cut out the rot and welded in new steel, I had obviously missed some and it continued to rot from inside.

It might have made life easier to have just taken the dash out before I started my footwell repairs as It's a sight easier to see and access with it out of the way.

That's enough for today. Next I have to decide what to cut out and replace. I'm also starting to worry how I'll get the whole thing put back together. Maybe I should start a spare parts business! :think: :lolno:

Keep on plodding. Be worth it when it's all done.

You don’t mess about Cliff do you .amazes me how you know where everything goes when you put it back together .

be great once it’s done .

be great once it’s done .

I'm not sure that I will be able to "put it back together"You don’t mess about Cliff do you .amazes me how you know where everything goes when you put it back together .

be great once it’s done .

Remember I’m only around the corner if you need a shoulder to cry on …I'm not sure that I will be able to "put it back together"

Last edited:

This "quick pre MOT ball joint dust covers fix" has significantly snowballed; talk about scope creep. A literal can of 'tin' worms!

Having gone as far as I have already, there's little point in shying away from going further. It was time to get the bonnet off again and get the air intake plenum off so that I have as much access to the scuttle as possible.

I'm annoyed with myself in that having already welded up the scuttle (6 years ago now) and then again when the screen was off and I sorted the screen surround, that I missed the water ingress problem that obviously still remained; I just hope I get it nailed this time.

There's this perforation to deal with ...

... and a couple of bits around the heater air intake.

It's the usual way forward from here ....

... cut out the rot ...

... all of it ...

make templates

cut the steel and shape and fettle to fit ...

... and tack weld in position

This is when the gas bottle runs out of course, so off to buy gas tomorrow.

Having gone as far as I have already, there's little point in shying away from going further. It was time to get the bonnet off again and get the air intake plenum off so that I have as much access to the scuttle as possible.

I'm annoyed with myself in that having already welded up the scuttle (6 years ago now) and then again when the screen was off and I sorted the screen surround, that I missed the water ingress problem that obviously still remained; I just hope I get it nailed this time.

There's this perforation to deal with ...

... and a couple of bits around the heater air intake.

It's the usual way forward from here ....

... cut out the rot ...

... all of it ...

make templates

cut the steel and shape and fettle to fit ...

... and tack weld in position

This is when the gas bottle runs out of course, so off to buy gas tomorrow.

Went for gas today, OMG! the cost has gone up a lot; £47 for a 9 ltr 5% CO2/Argon mix refill. Last time I got one it was about £32, so that's about a 50% increase.

It's been raining so I made the followup videos for fun

I've had an enforced lay off on the repairs. Last thing I managed to do was to finish off the scuttle repair so here's the photos.

I had to remove the bracket that supports the air intake plenum and patch yet another rusty area. Very annoying this as it's the second time I've had to repair this area. It shows how important it is to cut out 'all' rusty steel that I should be having to make repairs here again. Actually, to be fair to myself, I did cut out the rot but failed to stop water still getting in.

After dressing the welds, I applied filler ...

... and after rubbing down to get reasonably smooth surface, I relocated the bracket

I was sweating a bit worrying that I hadn't adequately marked the bracket position to re-attach it accurately.

I slapped on a bit of primer and then fixed the bracket in place.

Next it was the two small section around the heater air intake opening to replace

After the usual weld grinding and finishing, a generous amount of seam sealer was brushed on the various seams, and a coat or two of the primer was brushed on.

The very last job I ticked off the list was to refit the loom grommet into the bulkhead utilizing the hole I so carefully made for it.

You wouldn't believe the struggle I had getting that back in with loom running through it and lack of hand space. Anyway, managed eventually and it fitted like a glove! I'll run a bead of sealer around it too later to make sure it's water tight.

I had to remove the bracket that supports the air intake plenum and patch yet another rusty area. Very annoying this as it's the second time I've had to repair this area. It shows how important it is to cut out 'all' rusty steel that I should be having to make repairs here again. Actually, to be fair to myself, I did cut out the rot but failed to stop water still getting in.

After dressing the welds, I applied filler ...

... and after rubbing down to get reasonably smooth surface, I relocated the bracket

I was sweating a bit worrying that I hadn't adequately marked the bracket position to re-attach it accurately.

I slapped on a bit of primer and then fixed the bracket in place.

Next it was the two small section around the heater air intake opening to replace

After the usual weld grinding and finishing, a generous amount of seam sealer was brushed on the various seams, and a coat or two of the primer was brushed on.

The very last job I ticked off the list was to refit the loom grommet into the bulkhead utilizing the hole I so carefully made for it.

You wouldn't believe the struggle I had getting that back in with loom running through it and lack of hand space. Anyway, managed eventually and it fitted like a glove! I'll run a bead of sealer around it too later to make sure it's water tight.

Legendry work once again!

Great stuff enjoyed those vids ..very educational.It's been raining so I made the followup videos for fun

Bit the bullet today and got stuck into the offside. Removed yet more of the vehicle to gain access (I'll be as clued up as Heathy on breaking at this rate). Removed under dash fusebox, brake master cylinder, and brake servo. Just as well I did as what looked sound metal from inside the arch turned out to be rotten once I got a closer look and had a poke about. Oh well.

I've had to cut out a section of the arch same as on nearside...

... and a section of the footwell too

so you know what I'll be doing for a while longer.

I've had to cut out a section of the arch same as on nearside...

... and a section of the footwell too

so you know what I'll be doing for a while longer.

As always I admire you willingness to persevere. I gave up on mine when the FPR failed and the front steel steering pipes....