Lime Tree Heros

Accelerating Away

I hate wiring, so decided on a bit of carpentry instead... I know I'm putting it off and I know it'll come back to bite me...

So back into the back. My original thought was for a one piece unit running the length of the driver's side, incorporating a cool box, sink and burners, plug sockets, battery charger, 240v inlet, distribution box and grey water storage. However, due to physically manhandling the thing (and an 18mm error in woodcutting) this changed to become a two piece unit, that will bolt together.

First off I cut the base, recessing for the tool storage locker.

Next up, everything was sort of laid out, to test that it all fitted - cool box towards the front, sink / burners towards the rear, the 2 empty 5l containers will be grey water storage.

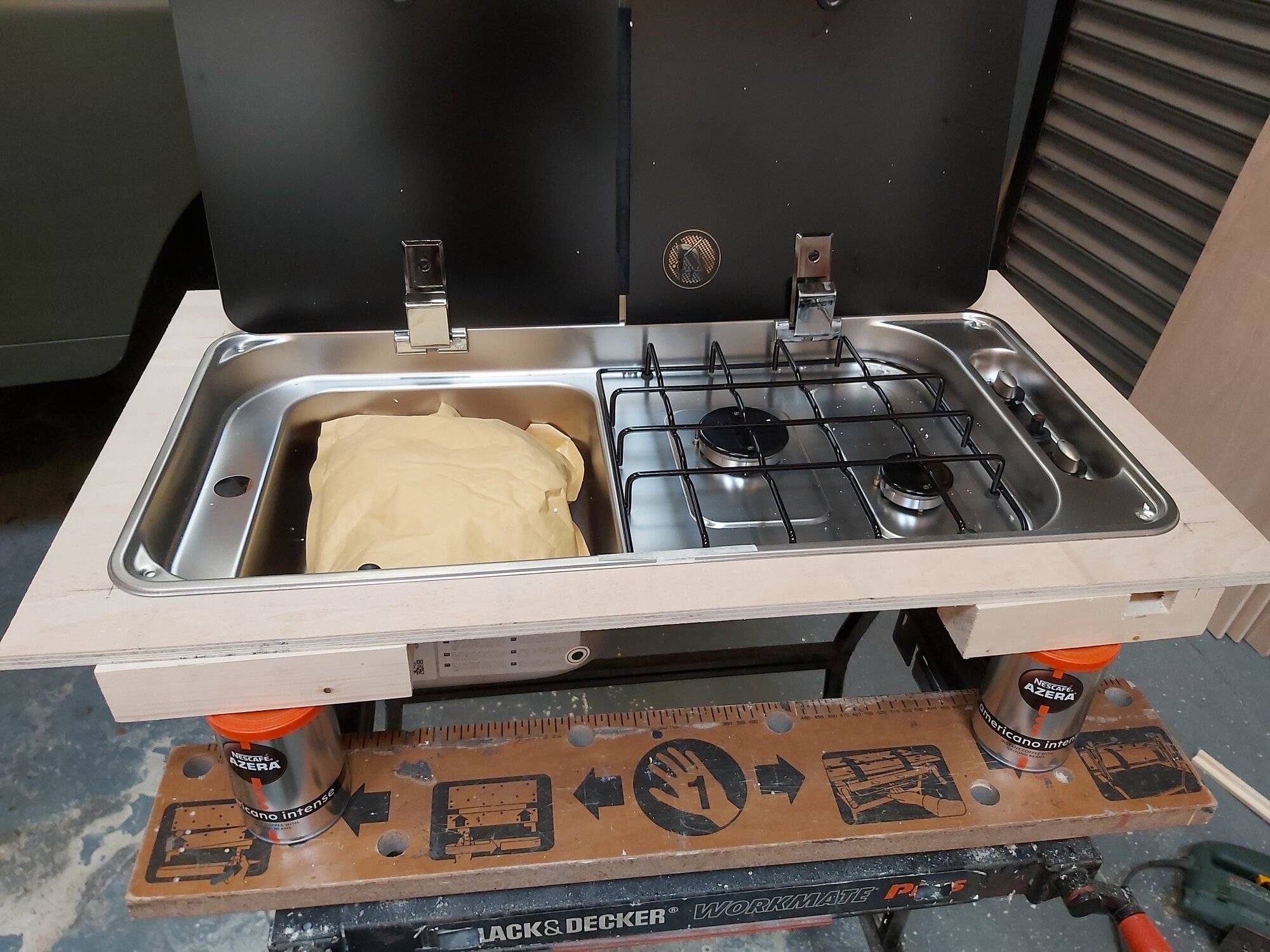

For reasons that I'm not too sure about I started with the rear section first, the burners / sink unit. Having cut the top, I marked out the cut out need for the sink / burners unit (the unit I bought had detailed instructions) having found my old school compass...

Once cut out, this was then rebated in the corners, as per instructions.

And the sink / burners unit test fitted.

Having cut the end panel, forward support panel and recessed the base for grey water storage, this was all then test fitted in the back.

Finally the front was cut, with access panels (think they'll be hinged flaps, but not yet definitive), incorporating the central beam that'll support my bed base. The black thingy in the lower RHS is the 240v inlet.

Next up, it all has to come out so it can be assembled permanently, or I could go back to wiring... However, The Ashes are on and there's a lot of cricket to watch, so progress may become somewhat delayed...

So back into the back. My original thought was for a one piece unit running the length of the driver's side, incorporating a cool box, sink and burners, plug sockets, battery charger, 240v inlet, distribution box and grey water storage. However, due to physically manhandling the thing (and an 18mm error in woodcutting) this changed to become a two piece unit, that will bolt together.

First off I cut the base, recessing for the tool storage locker.

Next up, everything was sort of laid out, to test that it all fitted - cool box towards the front, sink / burners towards the rear, the 2 empty 5l containers will be grey water storage.

For reasons that I'm not too sure about I started with the rear section first, the burners / sink unit. Having cut the top, I marked out the cut out need for the sink / burners unit (the unit I bought had detailed instructions) having found my old school compass...

Once cut out, this was then rebated in the corners, as per instructions.

And the sink / burners unit test fitted.

Having cut the end panel, forward support panel and recessed the base for grey water storage, this was all then test fitted in the back.

Finally the front was cut, with access panels (think they'll be hinged flaps, but not yet definitive), incorporating the central beam that'll support my bed base. The black thingy in the lower RHS is the 240v inlet.

Next up, it all has to come out so it can be assembled permanently, or I could go back to wiring... However, The Ashes are on and there's a lot of cricket to watch, so progress may become somewhat delayed...