Can you actually see where you going through that windscreen ?

-

Welcome to the Land Rover UK Forums

You are currently viewing the site as a guest and some content may not be available to you.

Registration is quick and easy and will give you full access to the site and allow you to ask questions or make comments and join in on the conversation. If you would like to register then please Register Now

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your Defender today?

- Thread starter caffn8me

- Start date

Geobloke

Posting Guru

Today Miffy officially shrugged off her Winter muff and is very much looking forward to a lovely summer  The only bad thing is that the A-bar blew over and broke one of the upper mounts which is a bummer... Fairly sure there was someone selling metal versions of the brackets. Anyone know who? Was it Massai?

The only bad thing is that the A-bar blew over and broke one of the upper mounts which is a bummer... Fairly sure there was someone selling metal versions of the brackets. Anyone know who? Was it Massai?

Dun nothing

Supposed to have started lining the rear cabin today.

Instead - spent the morning repairing a plumbing leak at home and the afternoon searching for a holiday. 'er indoors wants to get away for a bit. Holiday finally booked - will get back to my restoration tomorrow.

Supposed to have started lining the rear cabin today.

Instead - spent the morning repairing a plumbing leak at home and the afternoon searching for a holiday. 'er indoors wants to get away for a bit. Holiday finally booked - will get back to my restoration tomorrow.

Fiited a new lower steering column shroud. Too overly long because I hadn't realised the hole for the rear fog light switch wasn't cut out. It took me ages to find my rotary tool, much to my increasing frustration. I even went and did the food shopping on my own, so I could achieve something at least.

Anyway, finally got it fitted so it doesn't foul the steering wheel.

The whole instrument cowl is ill-fitting. So that's another job.

Anyway, finally got it fitted so it doesn't foul the steering wheel.

The whole instrument cowl is ill-fitting. So that's another job.

If I squint hard…Can you actually see where you going through that windscreen ?

Anyway, people see me coming and get out the way!

Show off! I have been trying to decipher that (with help from multiple sources from here) for months!Changed the oil in tranfer box and gearbox. Also decyphered how the interior lights are wired.

We have given Lancelot a clean - begun by a friendly Georgian farmer. Topped up his oil, lubed the universal joints and attacked the dog hair with vigour and a Karcher vacuum!

Since replacing the indicator/high beam stalk the steering column shroud has been offset...the ignition key slot is no longer quite how it should be. Hmm. I tried four times to get it right!Fiited a new lower steering column shroud. Too overly long because I hadn't realised the hole for the rear fog light switch wasn't cut out. It took me ages to find my rotary tool, much to my increasing frustration. I even went and did the food shopping on my own, so I could achieve something at least.

Anyway, finally got it fitted so it doesn't foul the steering wheel.

The whole instrument cowl is ill-fitting. So that's another job.

The Land Rover started on the button after at least 6 weeks so that was good .it certainly makes a difference with a huge battery .

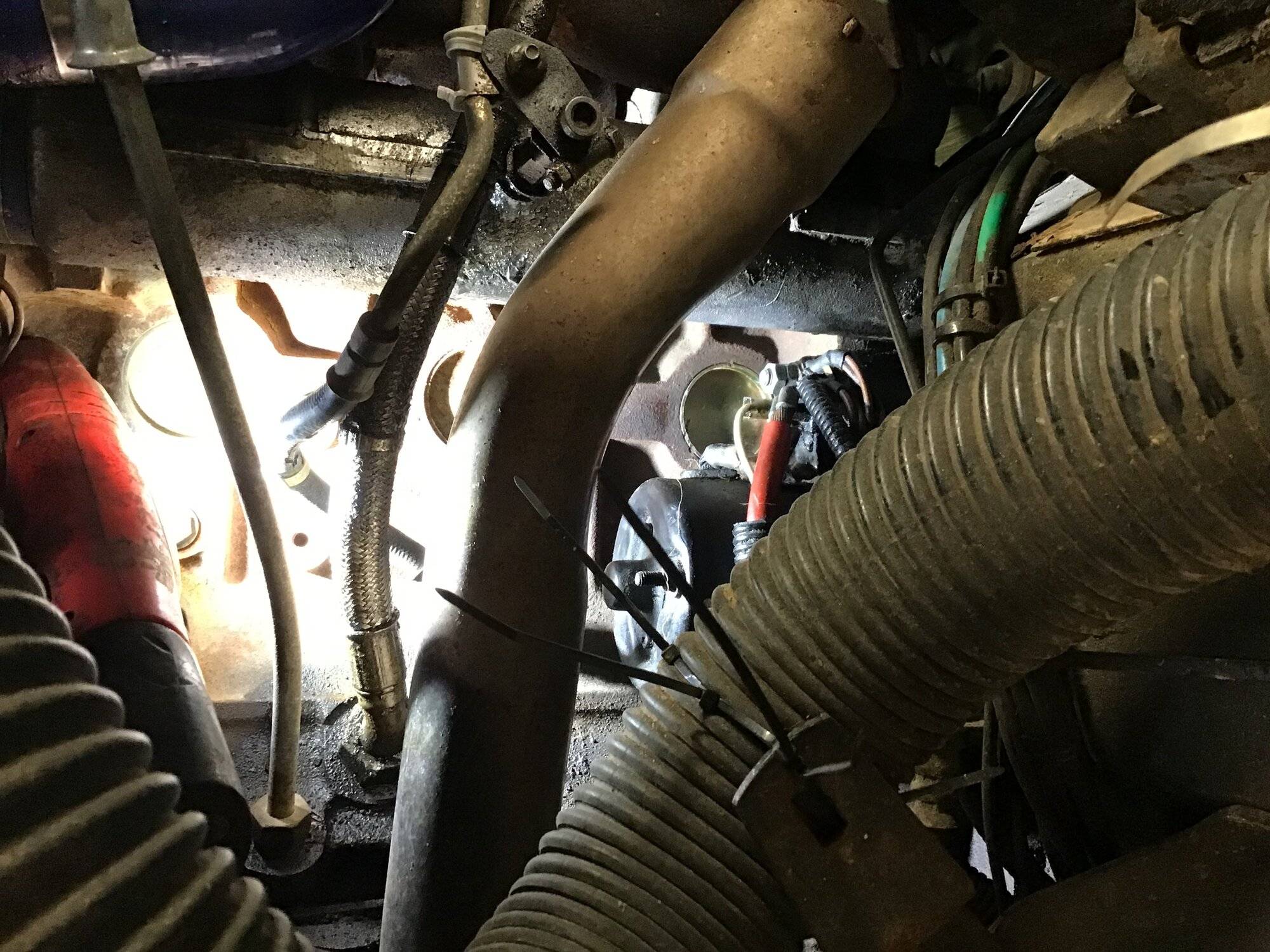

It was core plug day ..what a Barstaaarrrd of a job plenty of swearing don’t worry about that .i couldn’t do it ,how you guys build bloody land rovers is beyond me …anyway the day pand out .i rang my landy mechanic pal up he said I’m not busy pop it down …now bearing in mind it won’t hold water I clogged the hole up with cloth but it didn’t make to much difference the water pished out ..he’s only 3 mile down the road so took it easy and got there without it overheating.. the plug which had gone is behind the starter ,how are you meant to do it successfully with engine in you can’t get to it ?

With mine on a ramp and wheel off ,”Oh to have a work shop with a ramp”,I have no inner wings on mine so you can at least see what you’re doing ,a bit …he / we more him than me the new one is in and lock tighted in place ..

Ive given him my front diff seal to replace which has a slight leak. since he’s got time and the landy is inside the workshop until next week, no rush ..He’s a good fella to know .

It was core plug day ..what a Barstaaarrrd of a job plenty of swearing don’t worry about that .i couldn’t do it ,how you guys build bloody land rovers is beyond me …anyway the day pand out .i rang my landy mechanic pal up he said I’m not busy pop it down …now bearing in mind it won’t hold water I clogged the hole up with cloth but it didn’t make to much difference the water pished out ..he’s only 3 mile down the road so took it easy and got there without it overheating.. the plug which had gone is behind the starter ,how are you meant to do it successfully with engine in you can’t get to it ?

With mine on a ramp and wheel off ,”Oh to have a work shop with a ramp”,I have no inner wings on mine so you can at least see what you’re doing ,a bit …he / we more him than me the new one is in and lock tighted in place ..

Ive given him my front diff seal to replace which has a slight leak. since he’s got time and the landy is inside the workshop until next week, no rush ..He’s a good fella to know .

Out of interest he has this disco that he’s been breaking for awhile ,I do believe the engine has gone but the interior is there ,dash etc although somewhat open to the elements it looks pretty good if anyone needs anything.

Are those brake rotors black..?

YesAre those brake rotors black..?

As I'm not in a position to get on with meaningful work on truck atm I thought I'd amuse myself with the scope..

I added a couple of new probes to my collection.. Its actually possible to make them but they don't cost a lot..

A pulse sensor and a inductive pick up probe..

I'll have to come up with a more professional method of attaching it but today I just taped the inductive pick up to No1 injector

What I was hoping to do was establish where exactly top dead cntr is on my crankshaft or camshaft sensor traces..

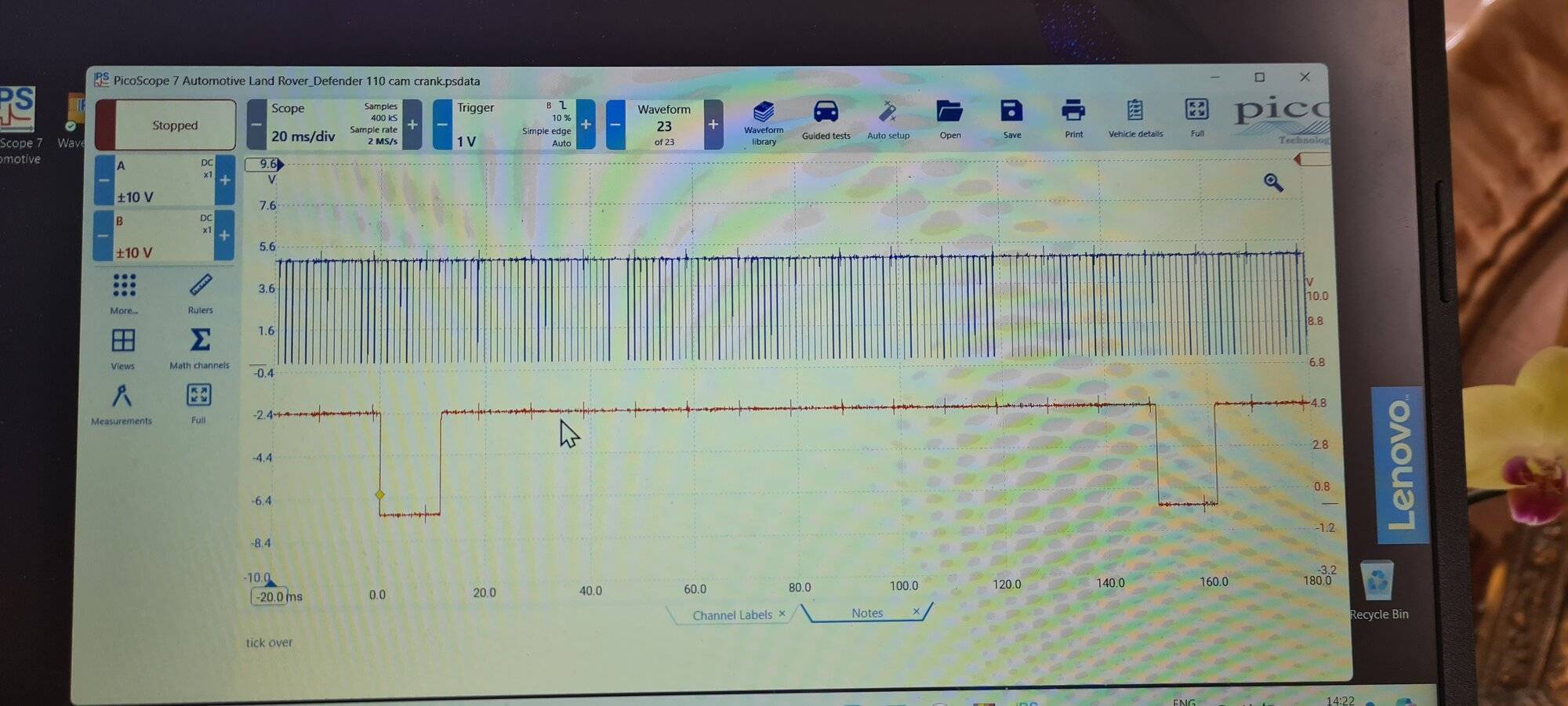

Blue is crankshaft which is a 60tooth wheel with two missing for the reference point represented by The wider gap in the blue trace..

The camshaft signal is used by the ecu to establish the correct cylinder to fire in the correct sequence. Its then ignored once running

At this point I was wishing I had a 4 channel scope to look at the firing of No1 injector on the same trace as the crank and cam signals..

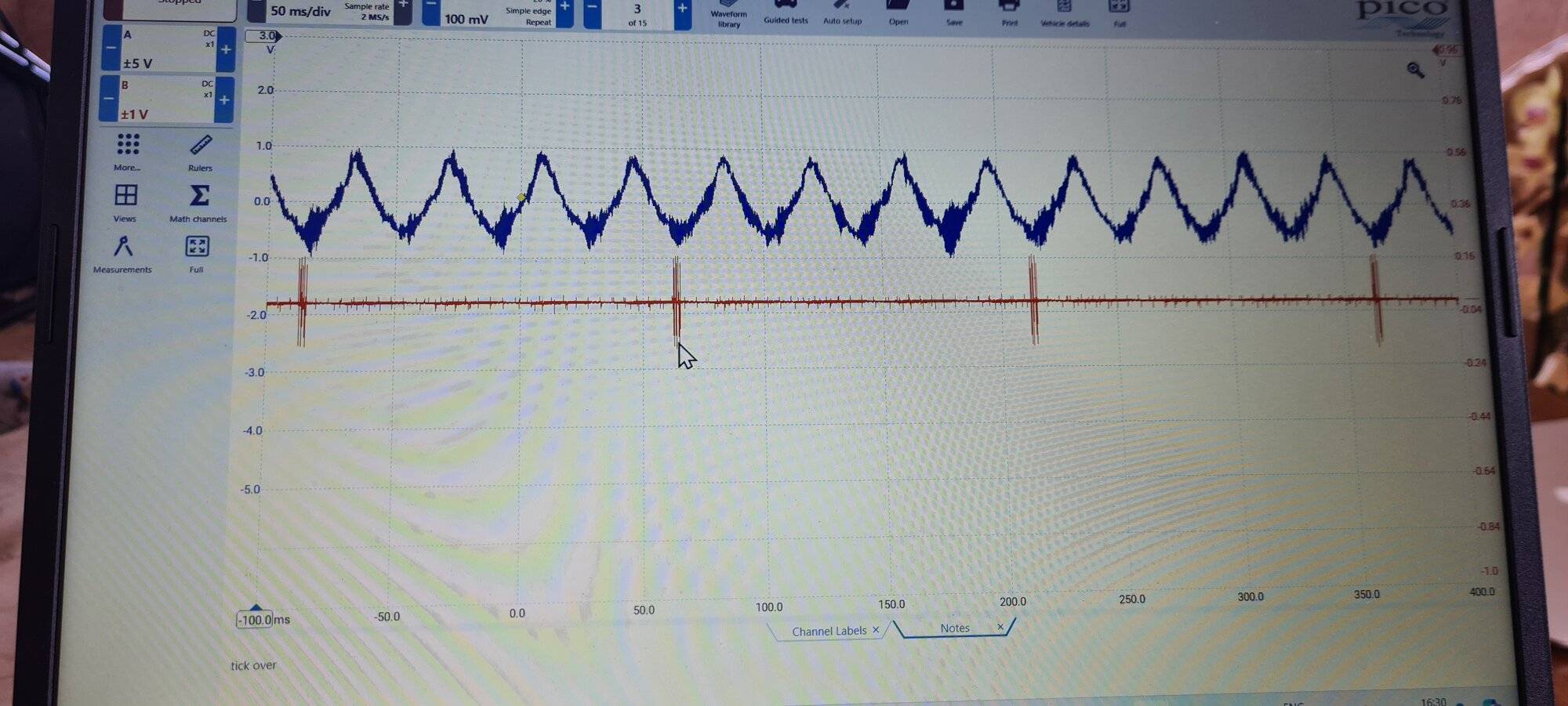

I don't so settled for crank with the inductive probe showing No1 firing relative to crank position sensor..

And from the above and knowing that it's a 60 tooth wheel so each gap in the crank signal represents 6 degrees, I can see that top dead cntr when injection takes place is 90 degrees (15 spaces) before the reference of two missing teeth on the crankshaft signal..

I gave the pulse sensor a try down the oil dip stick hole to check the crankcase pressure pulses.. Its a relative type test.. No definitive reading.. Just looking for similar amplitude and frequency of the pulses..

Used the inductive pick up just to identify No1 firing position on the trace

As an aside I noticed my front passenger electric window isn't working

..

..

Might be the switch connectors as I did have the cntr section of the dash out when putting in the coolant level alarm...

I added a couple of new probes to my collection.. Its actually possible to make them but they don't cost a lot..

A pulse sensor and a inductive pick up probe..

I'll have to come up with a more professional method of attaching it but today I just taped the inductive pick up to No1 injector

What I was hoping to do was establish where exactly top dead cntr is on my crankshaft or camshaft sensor traces..

Blue is crankshaft which is a 60tooth wheel with two missing for the reference point represented by The wider gap in the blue trace..

The camshaft signal is used by the ecu to establish the correct cylinder to fire in the correct sequence. Its then ignored once running

At this point I was wishing I had a 4 channel scope to look at the firing of No1 injector on the same trace as the crank and cam signals..

I don't so settled for crank with the inductive probe showing No1 firing relative to crank position sensor..

And from the above and knowing that it's a 60 tooth wheel so each gap in the crank signal represents 6 degrees, I can see that top dead cntr when injection takes place is 90 degrees (15 spaces) before the reference of two missing teeth on the crankshaft signal..

I gave the pulse sensor a try down the oil dip stick hole to check the crankcase pressure pulses.. Its a relative type test.. No definitive reading.. Just looking for similar amplitude and frequency of the pulses..

Used the inductive pick up just to identify No1 firing position on the trace

As an aside I noticed my front passenger electric window isn't working

Might be the switch connectors as I did have the cntr section of the dash out when putting in the coolant level alarm...

I find the only problem with this kind of technology Andy is ..it may tell me something I really don’t want to know …but very clever either way .its like digging for the in-depth problem that doesn’t really exist …As I'm not in a position to get on with meaningful work on truck atm I thought I'd amuse myself with the scope..

I added a couple of new probes to my collection.. Its actually possible to make them but they don't cost a lot..

A pulse sensor and a inductive pick up probe..

I'll have to come up with a more professional method of attaching it but today I just taped the inductive pick up to No1 injector

View attachment 529258

What I was hoping to do was establish where exactly top dead cntr is on my crankshaft or camshaft sensor traces..

Blue is crankshaft which is a 60tooth wheel with two missing for the reference point represented by The wider gap in the blue trace..

The camshaft signal is used by the ecu to establish the correct cylinder to fire in the correct sequence. Its then ignored once running

View attachment 529259

At this point I was wishing I had a 4 channel scope to look at the firing of No1 injector on the same trace as the crank and cam signals..

I don't so settled for crank with the inductive probe showing No1 firing relative to crank position sensor..

View attachment 529260

And from the above and knowing that it's a 60 tooth wheel so each gap in the crank signal represents 6 degrees, I can see that top dead cntr when injection takes place is 90 degrees (15 spaces) before the reference of two missing teeth on the crankshaft signal..

I gave the pulse sensor a try down the oil dip stick hole to check the crankcase pressure pulses.. Its a relative type test.. No definitive reading.. Just looking for similar amplitude and frequency of the pulses..

Used the inductive pick up just to identify No1 firing position on the trace

View attachment 529263

As an aside I noticed my front passenger electric window isn't working..

Might be the switch connectors as I did have the cntr section of the dash out when putting in the coolant level alarm...

I just find it interesting Paul..I find the only problem with this kind of technology Andy is ..it may tell me something I really don’t want to know …but very clever either way .its like digging for the in-depth problem that doesn’t really exist …

It takes an age to get familiar with a scope and be confident enough to interpret and trust what you are looking at...

But all that aside on today's modern vehicle it's I'd say essential.. Along with the scan tool..

It's good to have traces of what you know to be good when it's running well.. If you develop a fault a comparison can be useful

More scope play today..

This time using a current clamp on No1 injector along with the inductive probe..

The other day I noticed the inductive probe appeared to be showing multiple events within its active part of the firing of the injector..

I didn't think it was capable of such resolution so tried a current clamp which I knew would show the multiple stages of injection if they were happening..

First shot shows the firing of No1 on both current and inductive probe.

And this one is zoomed on on one of the firing events.. Clearly showing how the injector is pulsed even at tick over.

Which raised another point in my mind..

What sort of injector does my 2.2tdci engine have.. I always presumed electro mechanical/solenoid... But I'm now thinking piezo.. For a number of reasons..

I was told that piezo would be a much higher resistance.. And mine came in at a our 200Kohms each..

The firing current is low.. Between 4/5amps against more than double that for the solenoid type..

Unless someone tells me differently ..

..

I checked my glow plugs while I had the meter out and I have a duff one.. Another job at some point..

This time using a current clamp on No1 injector along with the inductive probe..

The other day I noticed the inductive probe appeared to be showing multiple events within its active part of the firing of the injector..

I didn't think it was capable of such resolution so tried a current clamp which I knew would show the multiple stages of injection if they were happening..

First shot shows the firing of No1 on both current and inductive probe.

And this one is zoomed on on one of the firing events.. Clearly showing how the injector is pulsed even at tick over.

Which raised another point in my mind..

What sort of injector does my 2.2tdci engine have.. I always presumed electro mechanical/solenoid... But I'm now thinking piezo.. For a number of reasons..

I was told that piezo would be a much higher resistance.. And mine came in at a our 200Kohms each..

The firing current is low.. Between 4/5amps against more than double that for the solenoid type..

Unless someone tells me differently

I checked my glow plugs while I had the meter out and I have a duff one.. Another job at some point..

Last edited:

0utcast

Shifting Up

So since the last update we've been for a weekend in the Cotswolds (last weekend). Had a great time again, saw some cool towns and areas. Visited Clarkson's farm shop, saw some nice cars and bought some overpriced lager. Got some nice plastic pint glasses for the Defender though!

So, onto the Defender stuff:

Completed before Cotswolds trip:

Still to do:

So, onto the Defender stuff:

Completed before Cotswolds trip:

- Hung a pole across the rear wall from one side of the roll cage to the other to hold up the curtain. Worked great, made some brackets that bolt onto the roll cage and hold the pole securely. Will take it down at some point and paint it pretty.

- Swapped the air mattress for a Z Fold foam mattress. Much better! Nearly as good as the mattress at home, very pleased with it. Just about fits in the back with the side facing benches, bit of a mare to wrestle into place, but great when in.

- Bought levelling blocks, camp table, and a 4 gang sockets to camper plug in thingy. Didn't use any of them on the trip, but hey I have them now at least.

- Upgraded the gas camp cooker with one from Costco. Much more substantial, with a metal hinged lid and 2 rings. I'm planning on having the propane bottle in the exterior locker, with a line run to the back door. Should be good?

- Committed to making the back a camper. Till now, I'd been wanting to have it modular, easy to set up as a camper, but also able to carry people in the back. The weekend trip made me realise that I just need to commit to it being a camper in the back, as it'll make life so much easier. To that end I've started to build a drawer system to fit in the bottom of the rear space, that the bed will go on. I've also decided to take out the rear benches to make assembling/ disassembling the bed easier. Bought and got some plywood cut at B&Q, have started the assembly progress. I'll post some photos when it's done.

- Bought a load of small bits in Ikea, like boxes, organisers, hanging racks, that kind of thing. Cheapest Ikea run ever!

- Finally found and bought a middle seat for the front. £46 on eBay, collected it today.

Still to do:

- Insulate the front cab. I also want to add another layer of insulation to the back, to double it up, and add some carpet over top to make it pretty.

- Finish the fold down table at some point. Maybe.

- Finally fit the driver side step. Found the offending bolt fouling step placement, so I can take that out, fit the step, and move the bolt.

- Build the rear drawer unit.

Attachments

Good news on the front diff seal ,it didn’t need one ,the mechanic came around today to see the tree in the neighbours fence he’s friend has a big grab which tomorrow is going to lift and cut the trunk up that’s done quite a bit of damage ..

Anyway getting back to the land Rover the leak was coming from the diesel overspill pipe between injectors which was running down onto my front diff. given the impression that I had a leaky seal, so put a new pipes on between injectors and that cured the problem… so tomorrow morning will be picking it up and then help cut the tree up..

Anyway getting back to the land Rover the leak was coming from the diesel overspill pipe between injectors which was running down onto my front diff. given the impression that I had a leaky seal, so put a new pipes on between injectors and that cured the problem… so tomorrow morning will be picking it up and then help cut the tree up..

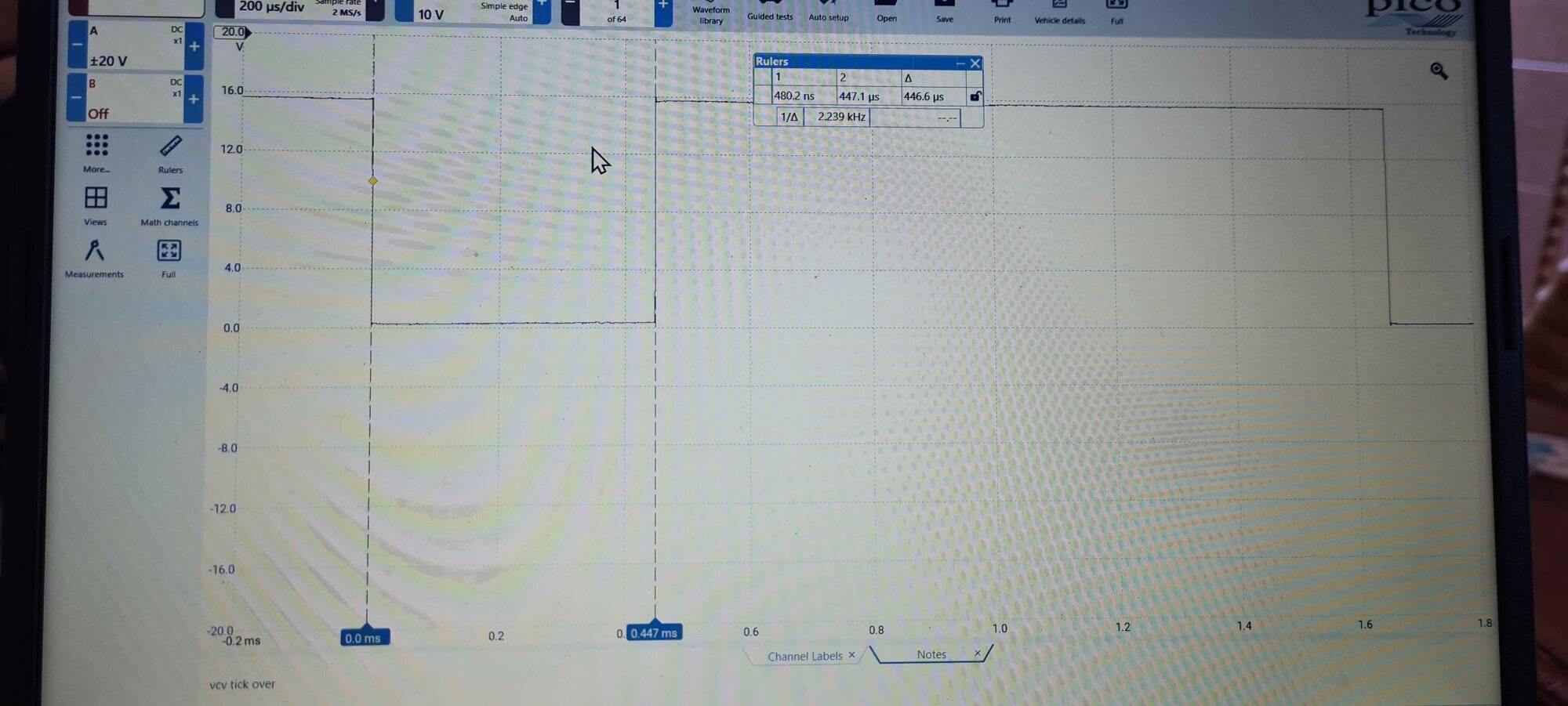

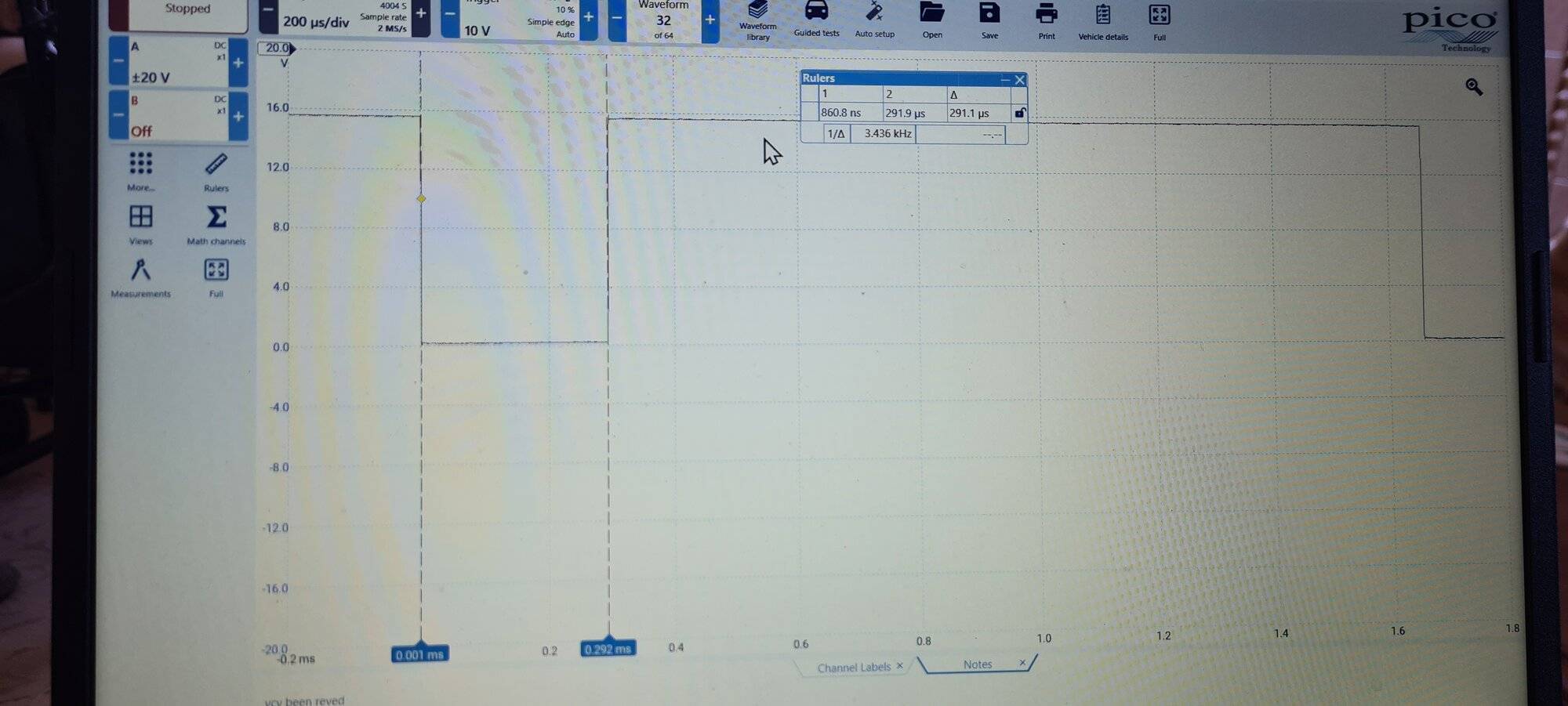

More scope work.. I've sort of finished with the injectors for now having established that my late defender with a 2.2tdci has piezo operated injectors..

So on to the vcv valve on the hp fuel pump..

After a bit of probing I sort of got it was a duty cycle or pwm operated valve but at tick over and even with a good few revs on it was difficult to see how the signal varied.. I think I'd need to see it under load and I haven't sorted a remote lead for the cab for that yet.. But at least I know, which wire is the signal now

I did alter the time base and got a shot of a single pulse.. Its easier to see the difference between idle and revving the engine at that time base..

The profile of the square wave(ie the time the valve is switched) differs by about 154 micro seconds between idle and putting on a few revs..

Riviting stuff

So on to the vcv valve on the hp fuel pump..

After a bit of probing I sort of got it was a duty cycle or pwm operated valve but at tick over and even with a good few revs on it was difficult to see how the signal varied.. I think I'd need to see it under load and I haven't sorted a remote lead for the cab for that yet.. But at least I know, which wire is the signal now

I did alter the time base and got a shot of a single pulse.. Its easier to see the difference between idle and revving the engine at that time base..

The profile of the square wave(ie the time the valve is switched) differs by about 154 micro seconds between idle and putting on a few revs..

Riviting stuff