Rivinuts are essentially captive nuts and are very useful when only one side of a panel is accessible.

You are likely to only come across these when fitting front light guards or a safari snorkel (or at least these are the only 2 times I have come across them).

The way they work

How to fit a rivinut

Tools and other things needed

Fitting (I am using a bolt with an allen key head in this example)

Drill hole as close to the diameter of the rivinut as possible. You need it to be quite tight as the side wall friction helps fit the rivinut. (if you do drill a hole too big see the "what if" section)

Screw nut on to bolt and then rivinut

Slot rivinut and bolt in to hole

Hold bolt still and push towards panel (effectively stopping it from turning)

Turn the nut in a clockwise direction, tighening the nut against the rivinut. This will draw the nut part of the rivinut upwards, it may be a little tough but it is working. Keep going until it doesn't turn anymore.

Remove bolt and nut and you're done.

What if?

If the rivinut turns in the hole then screw the bolt through a bit more and add a nut behind the rivinut too (see picture) and try again. This is why it is important to drill the holes to the same diameter as the rivinut.

Good Luck.

You are likely to only come across these when fitting front light guards or a safari snorkel (or at least these are the only 2 times I have come across them).

The way they work

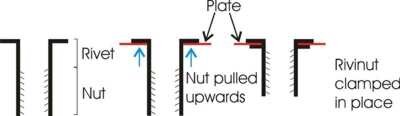

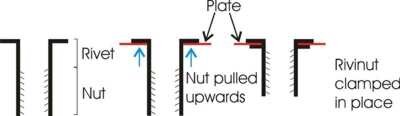

- The rivinut has 2 parts, the nut and the rivet.

- It is slotted in to a snug hole and the nut portion is pulled upwards, collapsing the rivet on itself.

- The rivet traps the metal plate (body panel) securely, done.

How to fit a rivinut

Tools and other things needed

- 1x bolt with same thread as rivinut and long enough to go through the rivinut

- 1x nut of same thread as bolt (can be a hex head or a round one like in the pics, stay away from slot and crosshead)

- 1x spanner for nut

- 1x spanner or allen key for bolt

Fitting (I am using a bolt with an allen key head in this example)

Drill hole as close to the diameter of the rivinut as possible. You need it to be quite tight as the side wall friction helps fit the rivinut. (if you do drill a hole too big see the "what if" section)

Screw nut on to bolt and then rivinut

Slot rivinut and bolt in to hole

Hold bolt still and push towards panel (effectively stopping it from turning)

Turn the nut in a clockwise direction, tighening the nut against the rivinut. This will draw the nut part of the rivinut upwards, it may be a little tough but it is working. Keep going until it doesn't turn anymore.

Remove bolt and nut and you're done.

What if?

If the rivinut turns in the hole then screw the bolt through a bit more and add a nut behind the rivinut too (see picture) and try again. This is why it is important to drill the holes to the same diameter as the rivinut.

Good Luck.